SYNERGi Premier Automated Manufacturing Cells

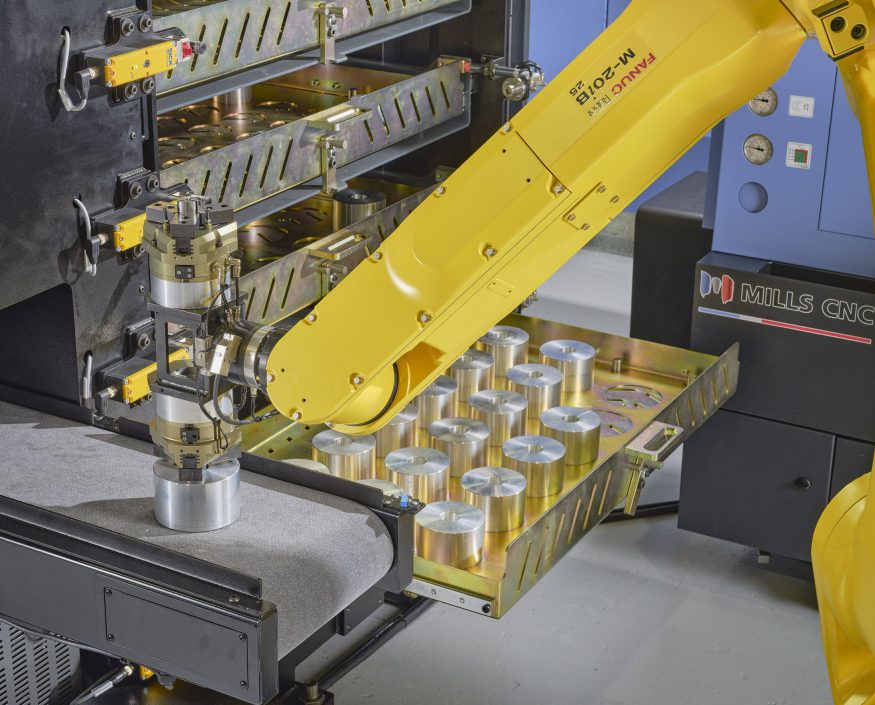

All systems feature a Fanuc industrial robot, a five (two-way) drawer system for part loading/unloading and a 17” touchscreen with onboard SYNERGi software.

In addition they also feature -: an inspection and parts’ ejector conveyor, an air blast end-effector, locating plates, pneumatic 2- or 3- jaw grippers, integrated SICK safety systems, industrial robot fencing and a (optional) part turnover station.

Main Features

Fanuc robot with 25kg payload capability.

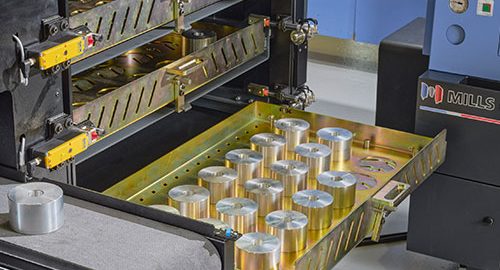

Two way drawer system (loading/unloading station).

Two way drawer system (loading/unloading station) showing parts’ inspection/ ejector conveyor.

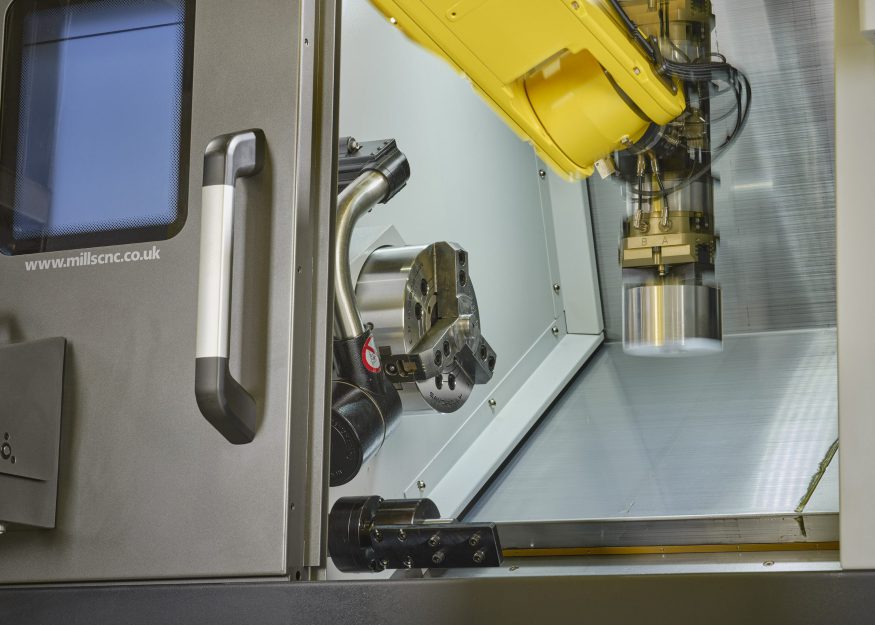

Pneumatic 2-jaw gripper (end effector). 3-jaw gripper also available.

Optional part turnover station.

HMI with keyboard.

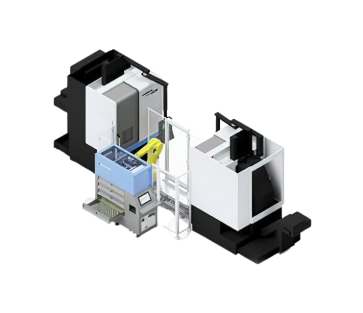

SYNERGi Premier Configurations

SYNERGi Premier automated manufacturing cell featuring a Doosan machining centre (side load).

SYNERGi Premier automated manufacturing cell featuring a Doosan machining centre (front load).

SYNERGi Premier automated manufacturing cell featuring a Doosan lathe.

SYNERGi Premier automated manufacturing cell featuring two Doosan machines (vertical turning lathes).

Technical Specification

Standard System

| Standard System |

Fanuc 6-axis: 25kg payload max Pneumatic grippers: 3-jaw or 2-jaw |

| Loading tray system |

5-drawer system: Two way Capacity: Part height (200mm); Part weight per draw (200kg) Draw dimensions: 900mm x 600mm |

| HMI |

17” touchscreen (separate keyboard) LAN connection |

| Safety Systems |

SICK integrated systems Inspection conveyor |

| Software |

SYNERGi software |

| Options |

Part turnover station Robot (7-axis rail) |

Interested In Industrial Robots? Get In Touch

Contact the team at Mills CNC to find out about our SYNERGi systems, or to get more details about industrial robot solutions.