Leading UK metrology equipment manufacturing specialist, Aberlink, invests in two new DN Solutions’ machine tools from Mills CNC.

The machines, the first DN Solutions’ machines acquired by Aberlink in its 33-year history, have significantly increased the company’s in-house machining capacity and capabilities helping to make its manufacturing processes more efficient, effective and productive.

Mills CNC, the exclusive distributor of DN Solutions and Zayer machine tools in the UK and Ireland, has recently supplied Aberlink Ltd., the largest UK-owned manufacturer of coordinate measuring machines (CMMs), vision systems and 3D measurement software, with two new DN Solutions’ machines.

The machines, a large-capacity DN Solutions’ DNM 6700XL (3-axis) vertical machining centre and a compact DN Solutions’ Lynx 2100LSYB multi-tasking lathe, were both installed, at the same time, at Aberlink’s recently revamped machine shop facility in Stroud, Gloucestershire, in March 2025.

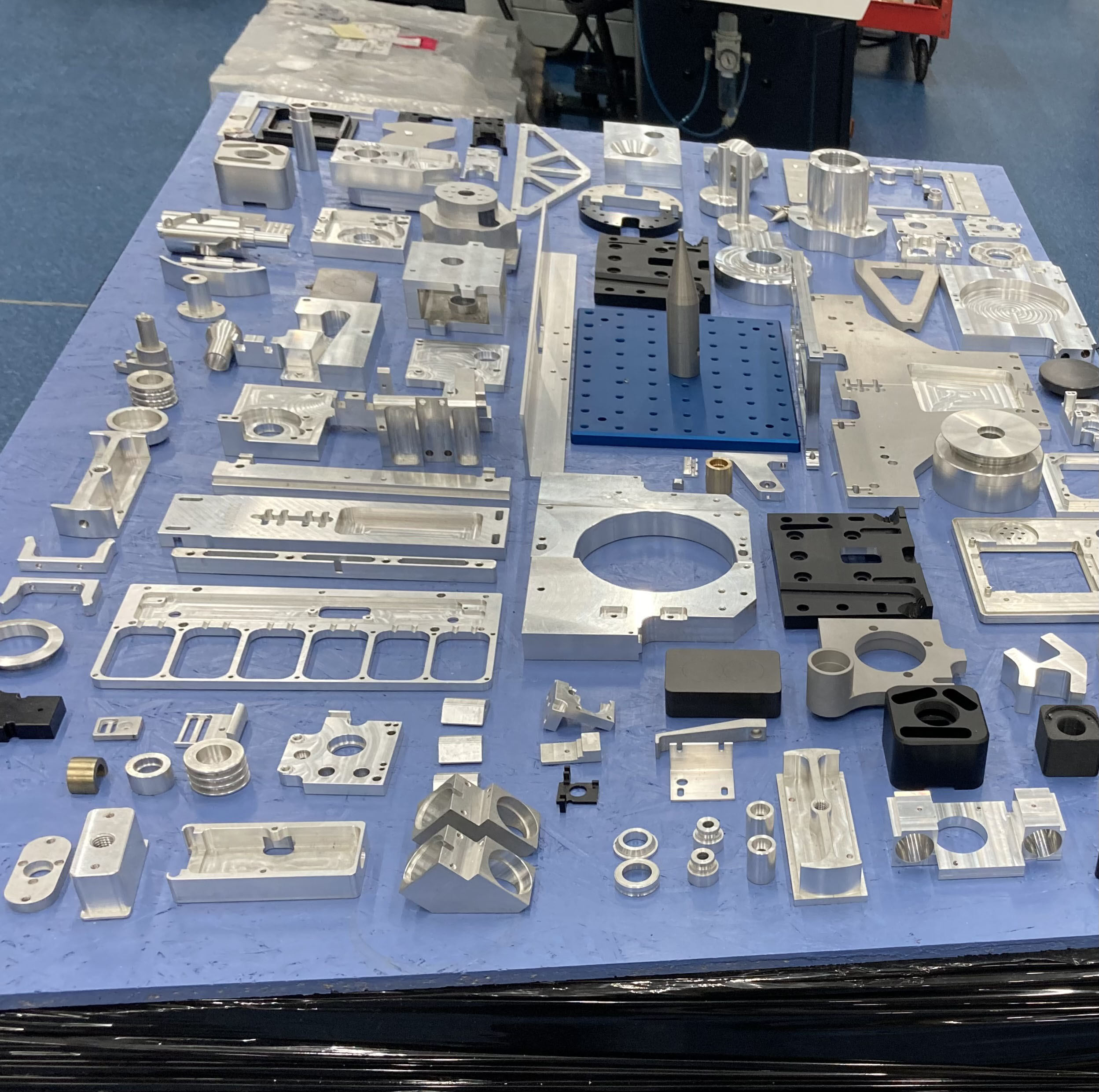

Since their arrival both machines have been put through their paces machining a range of high precision components that go into each and every one of Aberlink’s best-selling and innovative manual and CNC-controlled CMMs.

These components include different length and width CMM bridge beams and rails, air bearings, racks, plates, pinions, housings etc.), that are machined to tight tolerances and high surface finishes, in relatively small batches (i.e., up to 50-off) from a range of materials that include extruded aluminium alloy, aluminium billet and bar, steel, brass and engineering plastics.

Aberlink’s range of CMMs is comprehensive and impressive.

The range, that is constantly being developed, upgraded and improved, includes smaller shopfloor models (i.e., Fulcrum and Extol), where the CMM is positioned next to one or more machine tools in a customer’s machine shop, and larger bridge-type machines (i.e., Axiom, Halo, Horizon, Azimuth) that are often located in separate, dedicated and temperature-controlled inspection areas.

Irrespective of the model – manual or CNC-controlled, shopfloor or bridge-type, or Cartesian or non-Cartesian – Aberlink CMMs are globally recognised for their rigidity, accuracy (positional and repeatable), speed, reliability and ease-of-use. In 2024 the company received a King’s Award for Enterprise in recognition for the outstanding design innovation and error mapping of its Extol CNC CMM.

Another key differentiator of Aberlink’s CMMs is their affordability that, along with their build quality and the use and integration of Aberlink’s proprietary and revolutionary 3D software, has helped the company consistently drive-up sales and gain market share.

The company’s commitment to delivering value and affordability is further underscored by it providing its customers with free software upgrades and no annual maintenance fees…those often ‘hidden’ maintenance costs that can really get underneath customers’ skins!

It is not surprising then that Aberlink’s popular and proven CMMs are used, and are increasingly specified, by a growing number of UK and internationally-based precision component and mould tool manufacturers operating in the aerospace, automotive, motorsport, medical, oil and gas and energy sectors…to name but a few.

CMM manufacture and Aberlink’s machine shop

Aberlink’s CMM products are designed and built at the company’s manufacturing facility in Eastcombe, Gloucestershire. A majority of the company’s CMM components are made in house – the exception being granite bases/tables, servo motors and selected probing systems that are acquired from third-party suppliers.

The company’s manufacturing facility, as well as having an attractive visitor showroom, a recently expanded assembly area and dedicated software development, applications and customer service departments, also boasts a well-resourced machine shop divided into two discrete areas for milling and turning, and equipped with a number of CNC and manual machine tools – some of which are older ’legacy’ machines first acquired in the late 1990’s and early 2000’s.

Since being incorporated in 1993, the company has always had an in-house machine shop and this resource, ensuring component quality, fast turnaround times, manufacturing flexibility and controlled costs, has been central to Aberlink’s growth and development over the years.

“In the early days when we were designing and developing our first CMM which, incidentally, was Windows-based as opposed to being DOS-based, Aberlink started life, for the first two-years, being a precision subcontract machining specialist.

“Since then, to meet increased demand for our CMM products, the machine shop, in tandem with our sales performance, has grown substantially.

“Our machine shop therefore is, and has always been, a vital cog in the company’s growth and success”.

Marcus Eales, Owner and Director of Aberlink

New machine tool investment – rationale

To help cope with increasing demand for its CMMs, from both home and abroad (especially China), the company, back in 2024, undertook an audit to benchmark the performance and efficiency of its machine shop and to identify actual and potential production ‘pinch points’ and bottlenecks.

“Our machine shop is responsible for making a high volume of precision components that go into every CMM. For example, there are up to 150 different parts in our best-selling Axiom CMMs.

“To meet, often tight, customer delivery schedules it is important that the machine tools we have at our disposal and the machining processes we employ are efficient and up to scratch.

“The machine shop audit, undertaken as part of our company-wide continuous improvement programme, highlighted a couple of inefficiencies in our production process chain that we needed to address sooner rather than later.”

Marcus Eales, Owner and Director of Aberlink

The audit revealed an issue with an older, large-capacity (Siemens-controlled) Cincinnati FTV-640 machining centre that was being used to machine the company’s extruded aluminium CMM beams and rails.

Although the machine was still accurate it did suffer from relatively slow processing speeds that resulted in longer parts cycle times and, ultimately, in reduced productivity and throughput.

To improve its milling efficiencies the company ‘grabbed the bull by the horns’ and made the decision to replace the old machine with a new vertical machining centre and, as a consequence, drew up a ‘needs and wants’ machine specification checklist before approaching the market with its requirements.

The audit also, simultaneously, highlighted a capacity and capability issue with the company’s turning operations – specifically the time taken to process small diameter turned components.

It was determined that the set up and part cycle times required to machine complex, high-precision parts on its 2-axis (single spindle) lathes were too time consuming, required significant manual intervention and were (negatively) affecting efficiencies and productivity.

“Single-spindle, single-turret lathes are limited and can only perform turning, facing, drilling and boring operations on the centreline of rotation. They are also unable to produce off-centre holes, pockets or flat surfaces.

“The absence of a sub-spindle, and Y-axis and driven tooling capabilities meant that our lathes were not only creating a bottleneck, but were also putting pressure on our milling resource if and when milled features on a turned part were required.”

Ian Rhodes, Director at Aberlink

As a result, Aberlink made the decision to increase and improve its machining capacity and capabilities by investing in a new multi-tasking lathe as well as the aforementioned new 3-axis vertical machining centre.

Aberlink and Mills CNC

Before going to market, Aberlink did its homework and researched a number of different machine tool companies and took time to find out more about the machine tools in each of their portfolios.

Although Aberlink had not previously invested in machine tools from Mills CNC, its decision to acquire high-quality, competitively priced and readily available advanced machines automatically put Mills in the frame.

“Mills CNC has a good reputation in the market and with many of our customers too.

“The DN Solutions’ machines it sells are renowned for their excellent cutting capabilities, life-long precision and reliability.

“Furthermore, Mills’ after-sales service and support, often cited as being the best in the industry, helped put them in the box seat.”

Rachel Cook, Managing Director at Aberlink

Having discussed its milling and turning requirements with Mills CNC’s sales and technical staff, the company decided to invest in a new DNM 6700XL machining centre and a DN Solutions’ Lynx 2100LSYB multi-tasking lathe.

DNM 6700XL: a closer look

The DNM 6700XL is a large-capacity vertical machining centre with 2100mm x 670mm x 625 (X/Y/Z-axis travels), a 2200mm x 670mm worktable, fast rapid rates (30m/min) a powerful, high-torque spindle (18.5kW/15,000rpm) spindle and a 40-tool ATC.

The machine supplied to Aberlink featured the advanced Fanuc 0iM control and a Renishaw OMP60 and OTS workpiece and table probing system.

“Although comparable in size (i.e., its working envelope), the new DNM 6700XL is a faster and more powerful machine than the Cincinnati FTV-640 machining centre it replaced. The machine is flexible and can handle everything we throw at it, especially the rough machining of aluminium extruded beams.”

Ian Rhodes, Director at Aberlink

Lynx 2100LSYB: a closer look

The Lynx 2100LSYB is an 8” chuck/65mm bar capacity multi-tasking lathe equipped with a 6” sub-spindle, driven tooling (6,000rpm), a Y-axis (+/52.5mm), a 12/24-position turret and a 6,000rpm main spindle.

The machine supplied to Aberlink featured the advanced Fanuc 0iT control, quick-change collet chucks and a Hydrafeed Multifeed 65 short magazine bar loader.

“Having a multi-tasking lathe enables us to machine complex, high-precision parts in one hit.

“The investment in a bar loader has freed up the Lynx 2100LSYB’s potential enabling it to run unattended, and has helped us increase productivity, reduce costs and improve quality as a result.”

Marcus Eales, Owner and Director of Aberlink

Summary

Aberlink CMMs are high-end, sophisticated pieces of equipment.

To ensure they deliver the performance demanded of them, day in, day out, requires meticulous attention to detail all through the production process, from design and manufacturing through to assembly and testing etc.

Aberlink’s recent investment in two advanced DN Solutions’ machine tools from Mills CNC provides further evidence, if any more were needed, of the company’s commitment to quality and its determination to increase the process efficiency and productivity of its machine shop.

Final word

“We are delighted with the two new DN Solutions’ machines acquired from Mills CNC.

“Mills CNC is a proactive company and are easy to do business with. The installation of the machines, and the logistical support they provided throughout, was first-class resulting in minimal downtime and disruption.”

Rachel Cook, Managing Director at Aberlink