Nova Laboratories’ investment in BobCAD-CAM software and associated programmer training from Mills CNC’s Training Academy, improves the productivity and process efficiencies of its in-house machine shop.

The acquisition and use of powerful CAD-CAM software has been transformative.

High-precision prototype parts and finished components used in Nova Laboratories’ pharmaceutical processing and production machinery and equipment, for both its own licensed products and for its contract manufacturing operations, are being machined faster, more accurately and more cost-efficiently, vindicating the company’s decision to invest in an in-house machining resource.

Nova Laboratories’ in-house machine shop occupies a central and increasingly important role in the company’s production operations. But, to fully appreciate its pivotal role, and the reasons why it was established in the first place, it is important to first explore Nova Laboratories’ business in a bit more detail.

Background

Established in the 1993 by founder Dr Peter White and a team of NHS pharmacy colleagues, the company’s raison d’etre was to manufacture pharmaceuticals more effectively, efficiently and safely and, as a consequence, pioneered the application of gassed isolator technology and aseptic manufacturing processes used in pharmaceutical production.

The company designs, develops and manufactures its own licensed products in-house, with medicines to treat conditions for Acute Lymphoblastic Leukaemia (ALL), Sickle Cell Disease (SCD) and Inflammatory Bowel Disease (IBD) etc., being used worldwide.

The company also operates a highly-successful and growing contract manufacturing service for its clients, taking their products and developing robust aseptic manufacturing processes i.e., sterile, high-efficiency and integrated ‘fill and finish’ line systems and crimping solutions for customers’ clinical trial medicines and commercially available products.

To meet its own licensed product development and manufacturing requirements, and to ensure that its contract manufacturing service operates effectively, efficiently and profitably, Nova Laboratories designs and, in many cases, manufactures its own R & D and production-line hardware, machinery and equipment.

Specialist equipment, like isolators, are manufactured to Nova Laboratories’ tight design and performance specifications.

To keep the company’s new product development operations and its processing and production lines operating to full capacity, limiting machine downtime and processing equipment failure, is where the company’s machine shop comes in.

The machine shop

Designing and manufacturing new machinery and equipment and machining replacement and spare parts for existing machinery are the machine shop’s primary responsibilities.

Rather than leave this side of the company’s business to chance by outsourcing this work to external third party suppliers, Nova Laboratories, with its emphasis on innovation and the desire to control quality, achieve fast turnaround times and manage costs, took the decision in 2018 to do things ‘its own way’.

The company initially acquired a small local engineering workshop facility, that was adjacent to its main design and production operations, to be its dedicated in-house machine shop and, in addition to keeping some of the workshop’s existing manual machines (i.e., a lathe, a milling machine and a drilling machine), also employed the workshop’s time-served machinist, Steven Potter, to run the new facility.

Further investment in the machine shop’s plant and equipment, to meet demand, and ensure the fast turnaround of high-precision complex parts, has been continuous and is on-going.

In addition to building a new, modern and spacious on-site machine shop, the company has strengthened the facility’s machining capacity and capabilities by investing in two Fanuc-controlled (CNC) machines – a new Puma 2100Y II multi-tasking turning centre with Y-axis and driven tooling capabilities, supplied by Mills CNC in 2019, and a used 3-axis DNM 500 vertical machining centre that was installed in 2020.

So far, so good.

The need

However, to get the best and most from its CNC machine tools, and to fully-exploit their capabilities and potential, particularly with regard to the new Puma 2100Y multi-tasking turning centre, it became clear that further investment in a powerful and flexible CAD-CAM package was required.

“We had already invested in CAM software to create programs for the DNM 500, but needed something different and more bespoke for the Puma 2100Y.

“Although it was possible to programme the machine directly using the Puma 2100Y’s onboard EZ Guide system, this approach had its limitations, especially when machining complex, high-precision 3D parts with intricate features and details.

“Because we are increasingly being required to machine these types of parts, and with the emphasis always on ‘right first time’ quality and fast processing speeds, we knew we needed to invest in a CAD-CAM system that had been specifically designed for mill-turn machines and applications.”

Steven Potter, Machinist at Nova Laboratories

Investigating the market

As there are a myriad of different CAD-CAM suppliers on the market, and even more software packages available, it can be bewildering and intimidating for companies taking their first CAD-CAM steps.

Before any decisions were taken, staff from Nova Laboratories, primarily Steven Potter, researched the market and drew up a checklist detailing the specific CAD-CAM attributes and features required.

“It was important that we invested in a system that would meet our immediate and future needs. The CAD-CAM system needed to be powerful and flexible, capable of handling 2D and 3D part processing, be easy-to-understand and use, and be competitively priced.”

Steven Potter, Machinist at Nova Laboratories

Because Nova Laboratories already had good relationships with Mills CNC having acquired the Puma 2100Y directly from the company in 2019, and having also (subsequently) attended a four-day Fanuc programmer training course run by the CNC Training Academy, Mills CNC’s training arm, it was natural that the Academy was approached for their advice and input.

“CNC Training Academy staff were really helpful.

“Although we had heard of BobCAD-CAM, we didn’t really know that much about it. Having contacted Darren Clarke, BobCAD-CAM Product Manager at the Academy, a presentation on the system was arranged where its features and benefits would be demonstrated and explained to us in more detail.

“We liked what we saw and, because the Academy is a licensed UK re-seller of the software, staff there could also deliver on-site BobCAD-CAM training to get us up and running.”

Steven Potter, Machinist at Nova Laboratories

Based on the strengths of the BobCAD-CAM system itself, its affordability and the support provided by the CNC Training Academy, Nova Laboratories made the decision to invest in BobCAD-CAM software – and hasn’t looked back since.

BobCAD-CAM – an overview

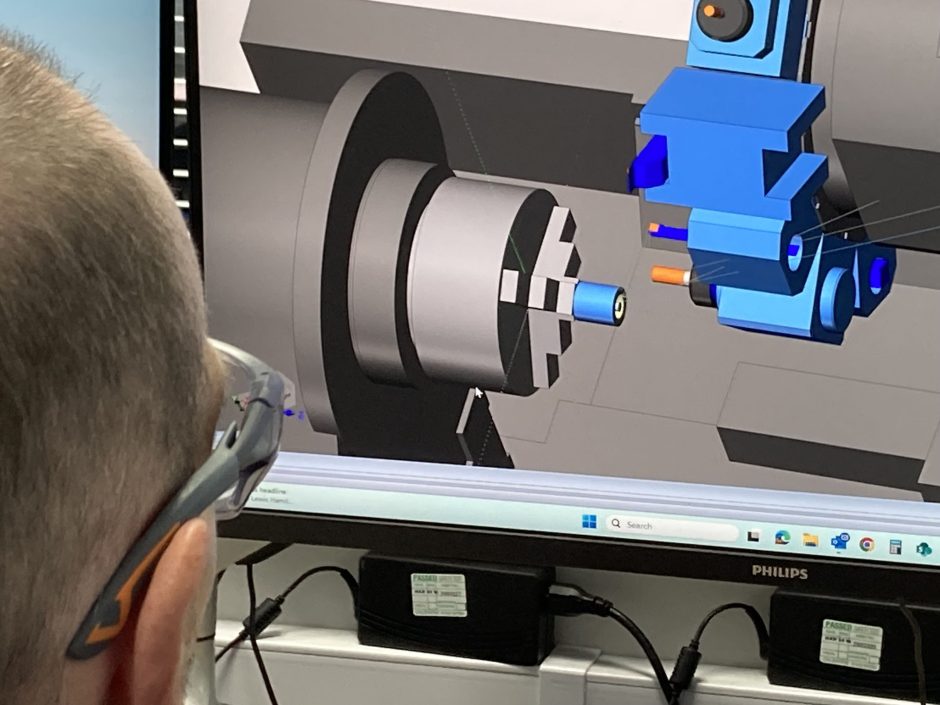

BobCAD-CAM is a powerful and flexible CAD-CAM system with a user-friendly interface, advanced toolpath options (for 2D, 3D and 4-axis and 5-axis machining) with full 3D simulation capabilities.

Simulation features help optimise toolpaths, detect programming errors in advance (prior to machining), and ensure that subsequent machining processes are fast, accurate and reliable.

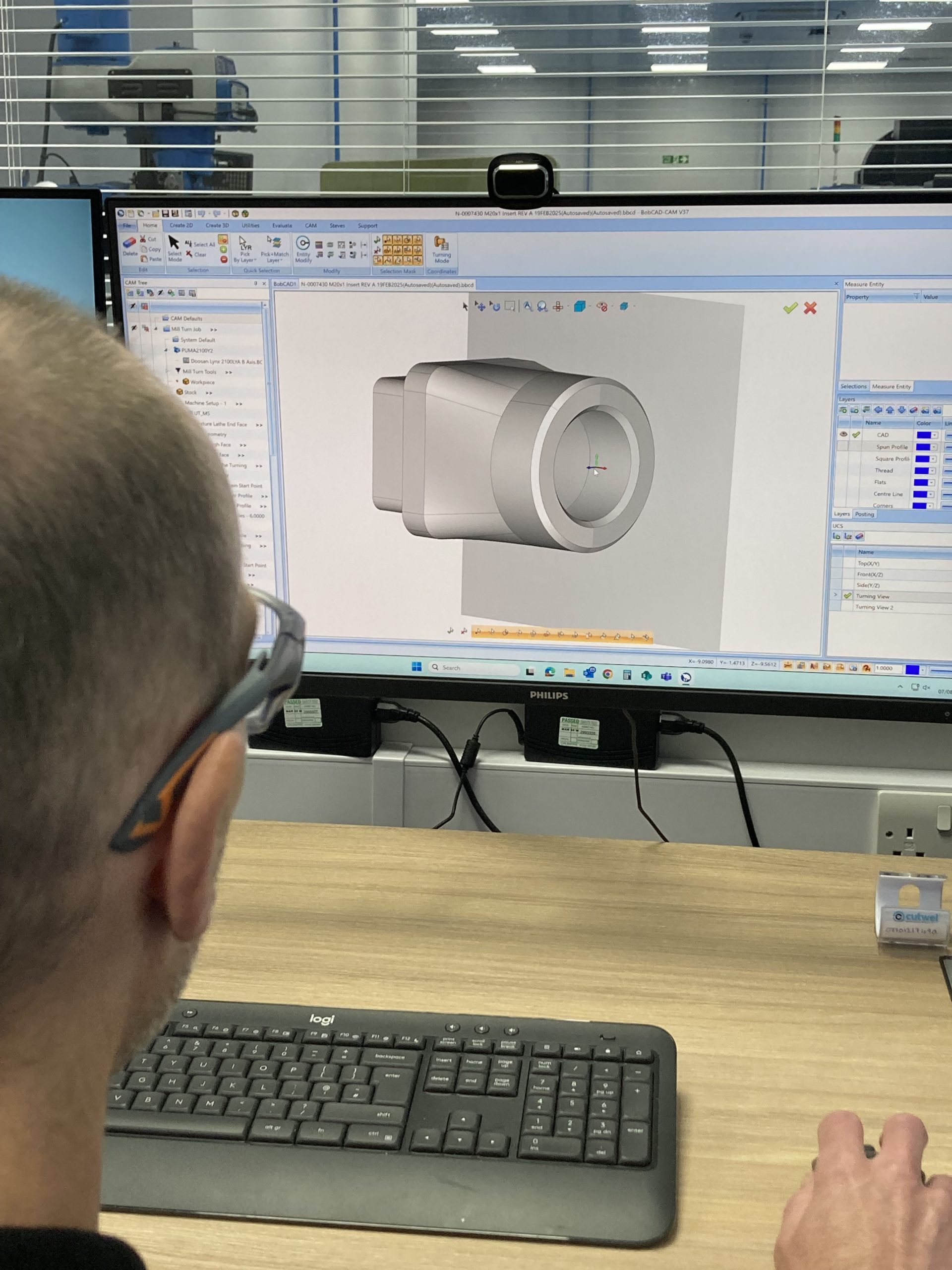

The system also provides comprehensive CAD capabilities for creating and modifying product designs and drawings.

“We use BobCAD-CAM more for its CAM, rather than CAD, functionality as our machines and equipment are designed, in-house, by our own design engineers using AUTODESK Inventor – a sophisticated CAD software system ideal for prototyping and product design and development.

“Completed 3D CAD AUTODESK Inventor files can be exported over to our BobCAD-CAM system for editing and design modifications, if required, or can be imported directly into BobCAD-CAM’s programming software (the CAM system) for toolpath creation, tool and machining strategy selection and machining parameter optimisation.

“Following simulation and G-code generation, the verified programs are sent (i.e., via USB file transfer) to the Puma 2100Y enabling fast and accurate part production.”

Steven Potter, Machinist at Nova Laboratories

Specific parts, many of them being ‘rush’ and emergency jobs, machined on the Puma 2100Y using BobCAD-CAM software have included original, replacement and spare stainless steel (316) components used/found in the company’s innovative and newly-designed pharmaceutical isolators (i.e., airflow control and venting system parts and assemblies that include high-precision machined nozzles, couplings, connectors, fittings etc.).

“The investment in BobCAD-CAM has been positive and has improved our quality and response times.

“From effectively a standing start, we are now able to make parts faster, better and more economically than before on the Puma 2100Y. BobCAD-CAM has been instrumental in helping us improve our process efficiencies and increase our productivity, and is helping us better exploit the machine’s part processing potential.

“Furthermore, BobCAD-CAM has also helped both elevate and strengthen the machine shop’s position in Nova Laboratories’ in-house production chain.”

Steven Potter, Machinist at Nova Laboratories