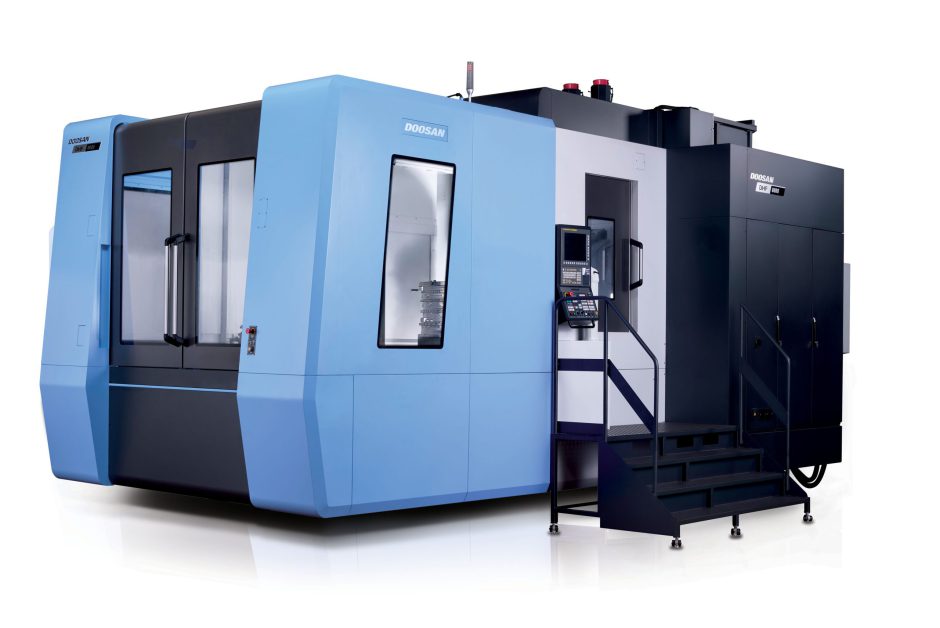

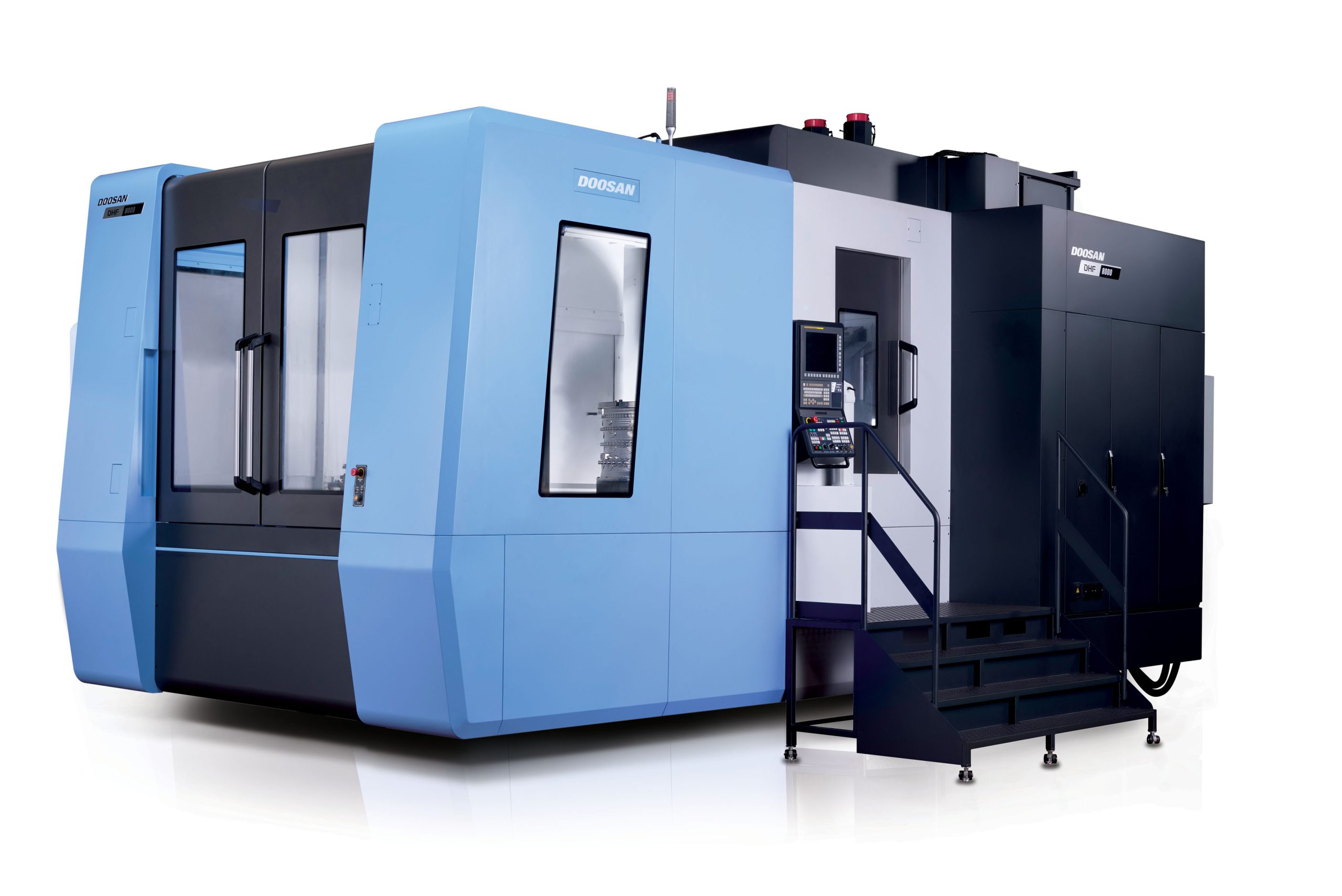

Following successful international launches first at Doosan’s DIMF Show (South Korea) in May 2015 and then at EMO (Milan) in October 2015, the new Doosan DHF 8000 – a large-capacity horizontal machining centre with simultaneous 5-axis machining capability – will make its UK debut on Mills CNC’s stand at MACH 2016 (Hall 5 Stand 5430).

The DHF 8000, one of 20 Doosan machines being showcased by Mills at MACH, is a high-performance, high-productivity machining centre designed to machine large, high-precision complex parts (in fewer set-ups and reduced processing times) for the aerospace and energy sectors (to name but a few).

The Fanuc 31i- 5 controlled machine features a powerful 35kW/6000rpm (960 N-m) ‘nodding-head’ spindle with +60/-100 degrees’ A-axis capability, a twin pallet configuration (each pallet is 800mm x 800mm in size accommodating work-pieces up to 2000kg in weight), and a high-capacity automatic tool changer (up to 196 tools).

The DHF 8000 is equipped with a HSK spindle (thereby widening its appeal to aerospace component manufacturers), but can also be supplied with a BT 50 spindle if required.

The machine can handle large work-pieces (X-axis = 1450mm; Y-axis = 1200mm; Z-axis = 1500mm), and boasts 40m/min rapid rates (X- and Y-axes) and 50m/min (Z-axis).

As well as being fast and powerful, the DHF 8000 is also accurate and productive and is equipped with dual ball-screws (Y- and Z-axes), a rigid and thermally-stable design and build; a high-efficiency chip evacuation system and a sophisticated cooling system for the machine’s spindle and ball-screws.

Says Tony Dale, Mills CNC’s Technical Director:

“The DHF 8000 is the next generation of large high-productivity horizontal machining centres from Doosan that provides manufacturers with full simultaneous 5-axis capability.

“The machine will be showcased on our Stand at MACH machining complex aerospace-type parts in one–hit, and to do this is equipped with a HSK – A100 spindle.”