Leading UK manufacturer of high-quality standard and bespoke industrial fasteners – RCF Bolt & Nut Ltd. – increases its in-house turning capacity by investing in a new DN Solutions’ Lynx 2100LB lathe from Mills CNC.

The arrival of the new machine, despite only being installed in October 2025, is already having a positive impact on the company’s productivity and process efficiencies helping it reduce production bottlenecks and improve lead time fulfilment.

Mills CNC, the exclusive distributor of DN Solutions’ and Zayer machine tools in the UK and Ireland, has recently supplied RCF Bolt & Nut Ltd., part of the TGM Industrial Group and a leading manufacturer of high-quality and high-performance standard and bespoke industrial fasteners, with a new compact, high-precision (2-axis) CNC lathe.

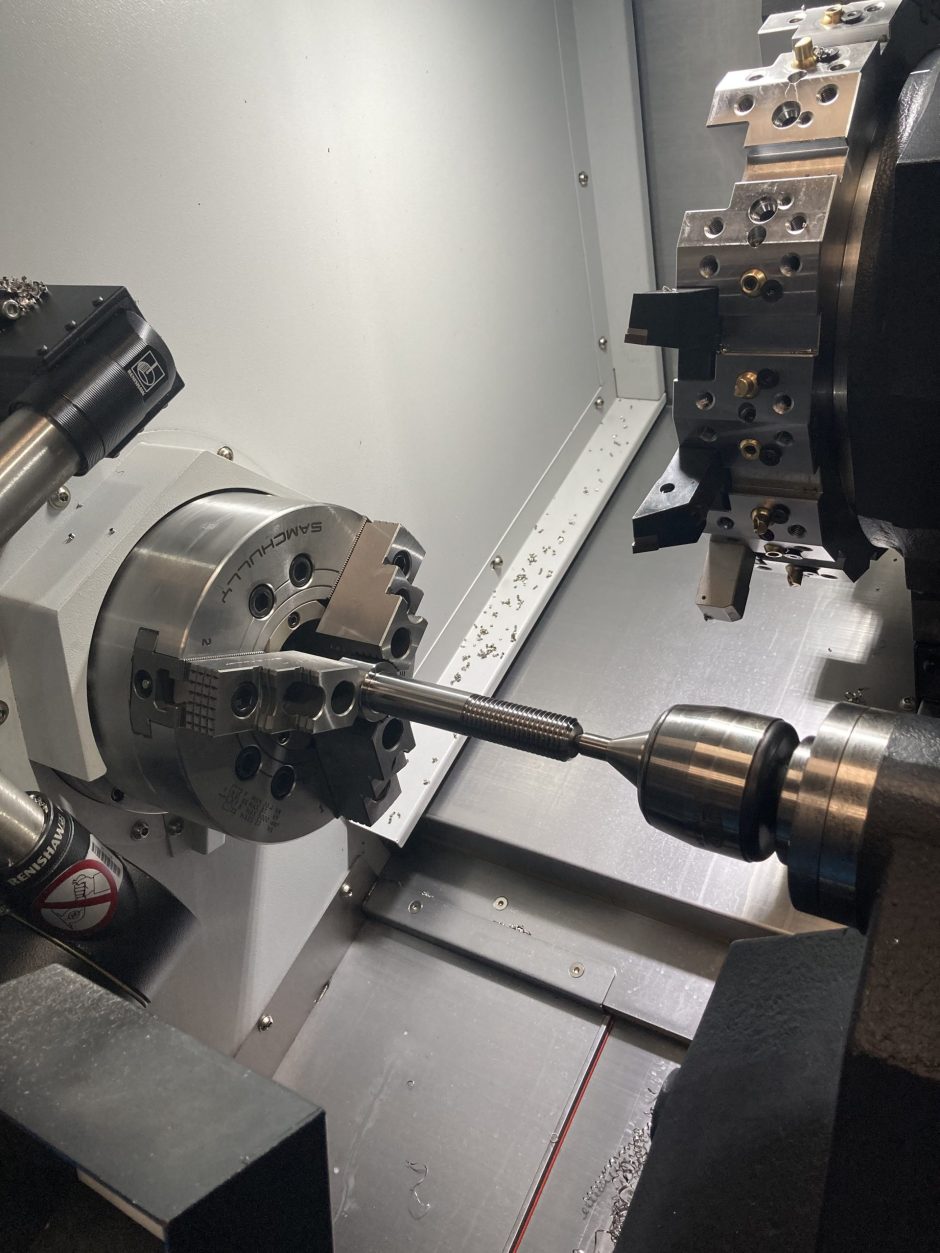

The machine, a Fanuc-controlled DN Solutions’ 8” chuck Lynx 2100LB, was delivered and installed, in October 2025, at RCF Bolt and Nut’s 40,000sq. ft. production and machine shop facility in Wednesbury, West Midlands.

Although only being installed a few weeks ago, the machine is already proving to be pivotal in helping the company improve its productivity and process efficiencies by reducing production bottlenecks and streamlining machining operations and, as a result, improving turnaround times.

RCF Bolt & Nut – quick overview

RCF Bolt & Nut, established in 1976, is ISO 9001: 2015 certified and currently employs 18 members of staff.

The company, primarily focused on the UK market, was acquired by the TGM Industrial Group in 2020, and is one of three industrial fastener companies in the Group’s portfolio – the other two companies being Union Fasteners (predominantly focused on international markets and overseas customers) and GSS Fasteners (a speciality niche fastener manufacturer focused on the UK structural applications).

Although RCF Bolt & Nut, Union Fasteners and GSS Fasteners operate independently, they do share resources and expertise, and can collaborate on projects.

This collective knowledge and experience in manufacturing industrial fasteners for highly-regulated industries and performance-critical applications, in addition to being experts on material compliance and conformity, and the machinability of different materials etc., enables the three companies, jointly and separately, to deliver innovative, high-quality standard and customised industrial fastener solutions to customers.

RCF Bolt & Nut is a vertically integrated business and has an impressive in-house hot forging operation at its disposal.

This, along with custom-designed tooling and machinery, produces a sizeable percentage of the steel bars and forged blanks the company uses to manufacture its range of industrial fasteners that include hexagon bolts and nuts, HSFG bolts (High-Strength Friction Grip), holding-down bolts, all-threads (threaded rods), tie-bars, coach screws, socket cap screws, gaskets etc.

The company also uses certified forged blanks and bar, supplied in a range of different sizes and grades, from an approved and preferred forging company in India.

RCF Bolt & Nut also has its own in-house machine shop, replete with a range of manual and CNC machine tools, to machine its products. These machine tools include sliding head lathes, horizontal CNC lathes, twin-spindle turning centres, polygon turning machines, thread rolling machines etc.

Machined parts, depending on their end application, can undergo a number of different secondary operations and processes before being delivered to its large and growing installed customer base with customers operating in, and serving, the power generation and power transmission, renewable energy, civil and structural engineering, oil and gas, water processing, rail and marine sectors…to name but a few.

These secondary processes, undertaken by a number of preferred suppliers, include zinc plating, galvanising, sheradising, PTFE coating etc. Laser marking for traceability purposes is undertaken in-house.

RCF Bolt & Nut prides itself on being able to respond efficiently to customers’ ‘small batch – quickly delivery’ fastener and fixturing requirements.

The company’s in-house forging operation, its well-resourced machine shop, the expert knowledge and experience of its staff and its comprehensive ranges of certified forged bar and blanks held in stock at its Wednesbury warehouse facility, optimise response times, ensure fast turnaround times and guarantee ‘best-in-class’ fastener solutions for customers.

The need

Since 2022, when RCF Bolt and Nut moved from its original Tipton location to the current Wednesbury site, business has been booming.

“We are on a strong growth trajectory and demand for our standard and bespoke solutions has been growing exponentially over the past few years.

‘Whilst this was, and is, good news the downside was that it was putting pressure on our in-house machining resources, creating production bottlenecks and pinch points, and ultimately affecting turnaround times.

“To help address this situation we began to subcontract-out our machining requirements to third party suppliers.”

Adrian Garrett, Managing Director at RCF Bolt & Nut

Whilst this was expedient, it proved in the longer run to be an expensive solution and began to affect the company’s ability to meet its customers’, often stringent, delivery schedules and deadlines.

“As a consequence, and as part of our integrated continuous improvement programme, we soon made the decision to take back control over our machining operations.

“We were on a mission to increase and improve our in-house machining capacity and capabilities, and, as such, decided to invest in new advanced machine tool technologies and develop our own robust machining processes in order to lessen our dependence on third party suppliers and provide a better service to customers.”

Adrian Garrett, Managing Director at RCF Bolt & Nut

Serendipity

In January 2025, Adrian Garrett, visiting PT Engineers Ltd., in Rugby, another company in TGM Industrial Group’s stable, noticed a (2019) Doosan Lynx 220LM lathe in the company’s machine shop that wasn’t being used and looked in pristine condition.

The 6” chuck, Fanuc-controlled multi-tasking lathe with an integrated C-axis and driven tooling capabilities was, as it transpired, surplus to PT Engineers’ requirements, and this led Mr Garrett to enquire about the machine’s availability, and the chances of bringing it into RCF Bolt & Nut’s machine shop.

“Straight away, I liked the look of the Lynx 220LM.

“I knew that a high-accuracy and flexible lathe would prove to be a useful addition to our machine shop and would provide us with the additional machining capacity we were looking for.”

Adrian Garrett, Managing Director at RCF Bolt & Nut

The Lynx 220LM was installed at RCF Bolt & Nut’s machine shop in February 2025 and had an immediate and positive impact on cycle times, literally reducing processing times by as much as 50% on various parts.

So far, so good.

However, with demand for RCF Bolt & Nut’s products and solutions still increasing and with the Lynx 220LM and the company’s other CNC machines working flat out, machining capacity was soon ‘swallowed up’.

“We needed additional machining capacity, and we needed it fast.”

Adrian Garrett, Managing Director at RCF Bolt & Nut

Lynx 2100LB investment decision

RCF Bolt & Nut’s positive experience with its Lynx 220LM lathe led it to contact Mills CNC, in Summer 2025, to discuss its immediate machining requirements.

“Additional capacity was the name of the game. We didn’t need as sophisticated a machine as the Lynx 220LM this time around, but instead, required a fast, high-accuracy and reliable 2-axis lathe that could help free-up capacity on the Lynx 220LM by handling parts requiring single-point threading operations and no milling element.

“We were introduced to the Lynx 2100LB and could see that its technical capacity and capabilities fitted the bill, perfectly.

After confirming price and availability, we placed the order for the new Lynx 2100LB with Mills CNC.”

Adrian Garrett, Managing Director at RCF Bolt & Nut

Lynx 2100LB: a closer look

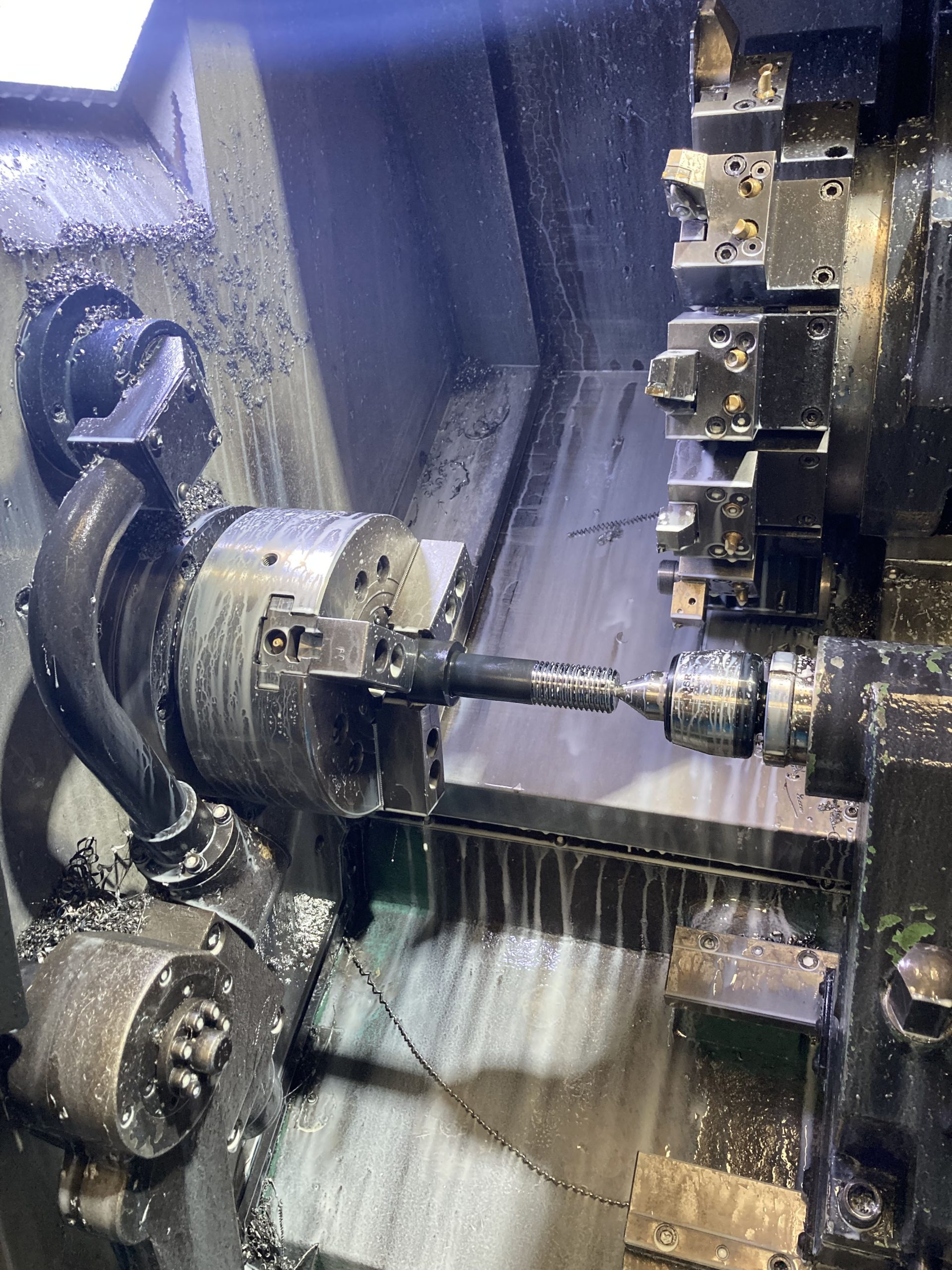

The Lynx 2100LB is a popular and proven compact lathe with a 350mm maximum turning diameter and a 550mm maximum turning length. The machine is equipped with a powerful, high-torque 15kW/4500rpm spindle (169N-m), a servo-driven 12-station turret and the advanced Fanuc iPlus control with a 15” touchscreen iHMI.

The Lynx 2100LB has a long bed and a rigid design and construction, and features roller-type LM guideways for high and repeatable accuracies and a hydraulic tailstock for handling longer shaft-type parts, and the model supplied to RCF Bolt & Nut also featured an automatic tool setter, a high-efficiency swarf conveyor and a FilterMist oil mist extraction system.

Lynx 2100LB in action

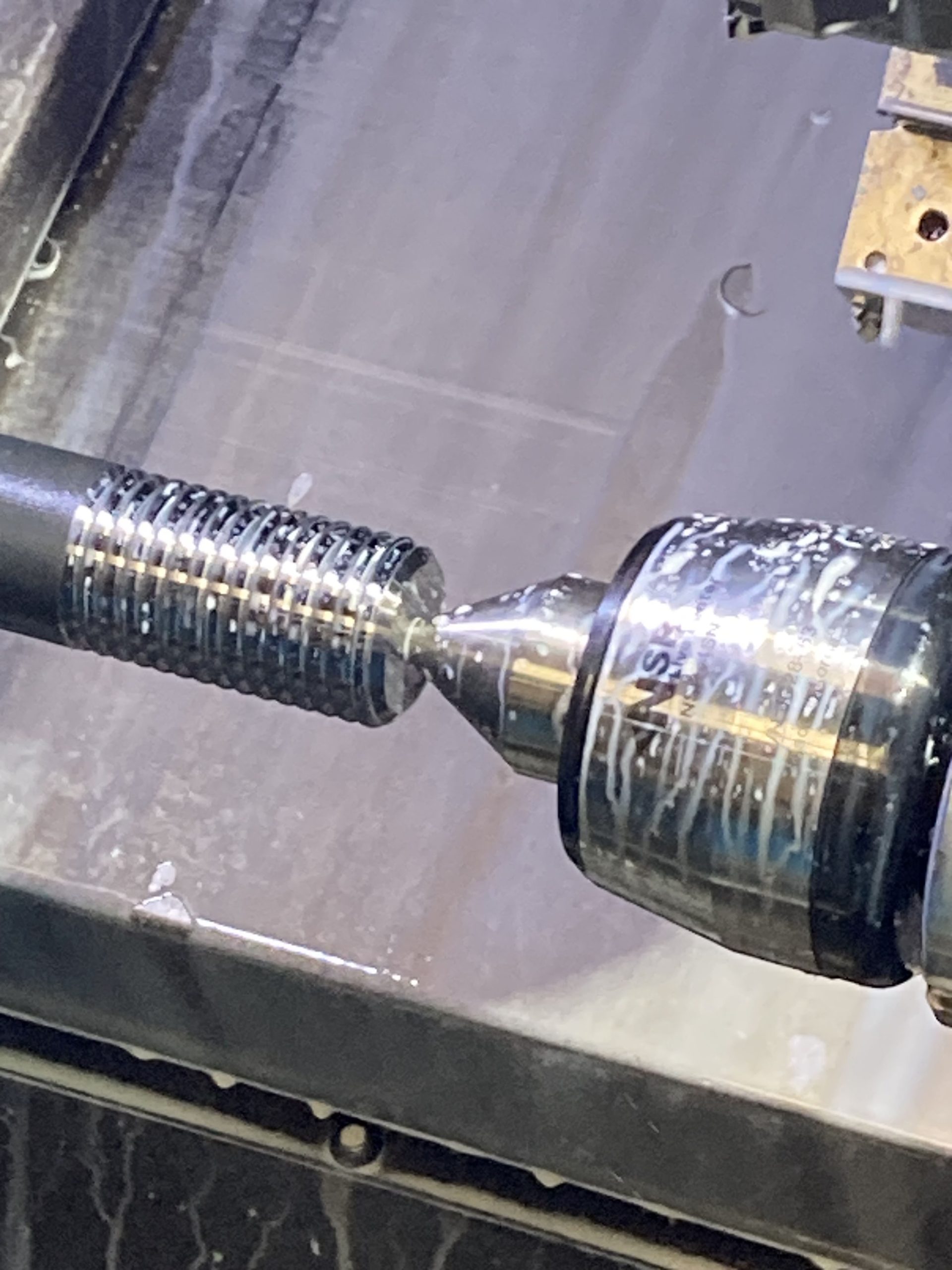

Since its installation, the Lynx 2100LB has been put through its paces machining, to high accuracies, different length and diameter ‘near net shape’ forged bolt and nut blanks made from a range of different materials and grades that can include high tensile strength steel alloys, stainless steels (i.e., Stainless 316), Duplex stainless steels, titanium, Inconel etc.

Machining operations undertaken on the new Lynx 2100LB, after first reducing the blanks down to size, include internal and external single-point threading, boring, reaming, rigid tapping, chamfering and parting off etc.

Components machined on the new Lynx are characterised by their tight, tied-up tolerances and exacting surface finishes with batch sizes ranging from one- and two-off through to 200-off, although larger batches can be accommodated. Machining part cycle times are typically short, usually no more than four-to-five minutes to complete all front- and back-end operations.

Summary

RCF Bolt & Nut is a growing and successful company committed to quality, innovation and customer service.

To maintain its market-leading position, the company regularly invests in its people, in its plant and equipment and in its processes and systems.

RCF Bolt & Nut’s recent investment in a new DN Solutions’ Lynx 2100LB lathe from Mills CNC has strengthened the company’s in-house machining capacity and capabilities, enabling it to improve productivity levels, increase process efficiencies and maintain its competitive edge.

“The new Lynx 2100LB is a fast, accurate and flexible machine. Its acquisition is evidence of our continuous improvement programme in action, and we are aiming to continue upgrading our machine shop in the months to come.

“We have, through acquiring the Lynx 2100LB, developed a good working relationship with Mills CNC and value their input and advice.”

Adrian Garrett, Managing Director at RCF Bolt & Nut