The winning formula!

It’s all systems go here at Mills CNC to make sure that our attendance at MACH 2026 is successful as it can possibly be – for you and us.

We’ve thought long and hard about the range and type of technologies we’re going to showcase on our Stand (HALL 19 – STAND 110), and, with our focus firmly on advanced multi-axis and multi-tasking machine tools, and high-productivity and high-efficiency automation systems, the deliberations are over, and the exhibition product line-up has now been finalised.

DN Solutions’ machine tools

Milling machines

We’re taking a total of 11 DN Solution’s machines to MACH 2026, a number of which will be making their MACH Show debuts.

Our milling machine tool line-up includes three models from our best-selling DVF range of simultaneous 5-axis machining centres (2 x DVF 4000 models and a DVF 5000Mk II) equipped with either the latest Fanuc CUFOS or recently- introduced Siemens ONE control systems, and one of these machines, the DVF 5000 Mk II, will be integrated with a multi-level automatic workpiece pallet-changer (AWC) that increases the machine’s productivity potential still further.

Whilst we’re on the subject of automation, we’ve made the decision, for the first time ever, to showcase a new NHP 5000 horizontal machining centre integrated with a linear pallet system (LPS) this time around. This compact, modular (expandable) and multi-pallet automation solution is inherently flexible, and significantly improves productivity and process efficiencies.

Other milling highlights will see two models from our ever-popular (Fourth-Generation) DNM vertical machining centre range, a DNM 4500 and a DNM 6700, take centre stage.

These machines, firm favourites with UK and Irish component manufacturers, feature powerful, directly-coupled spindles, large working envelopes and can be supplied with Fanuc, Siemens or Heidenhain controls.

Lathes

No MACH Show would be complete without one of our compact Lynx lathes making an appearance.

At MACH 2026, a 6” chuck Lynx 2100SYA Y-axis sub-spindle model will be showcased in close proximity to an ultra-high-productivity 10” chuck/81mm bar capacity TT 2100SYYB twin-spindle/twin-turret turning centre with dual Y-axis capabilities.

Both machines provide manufacturers with proven multi-tasking machining capabilities, ensuring fast small part processing in one set up.

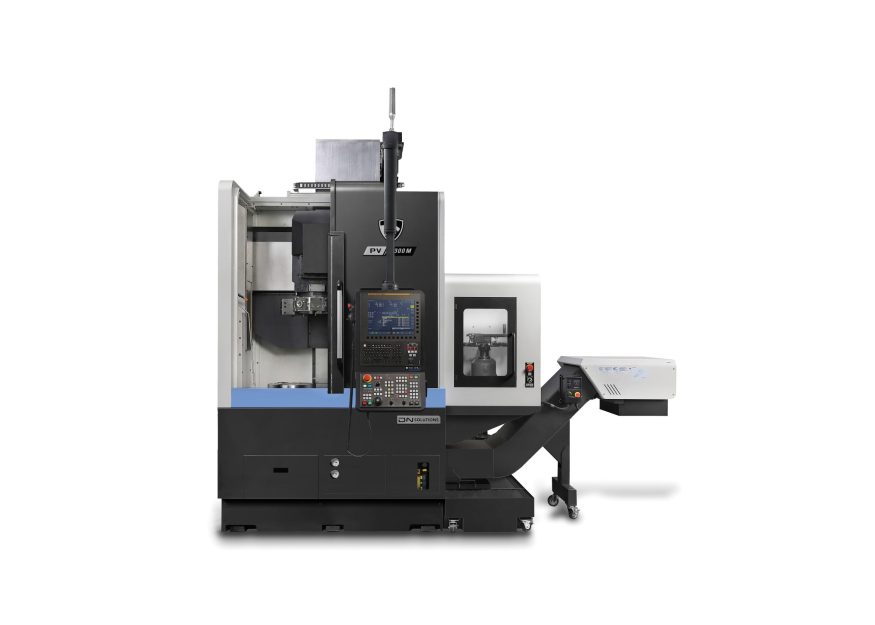

The lathe line-up is completed with a new, heavy-duty 18” chuck Puma V6300M vertical turning lathe with driven tooling (5000rpm) that will be making its debut at MACH 2026.

Mill-turn machines

Two high-performance, multi-tasking mill-turn machines will, we are confident, pull in the crowds at MACH 2026.

A new DNX 2100SB (Advanced) entry-level mill-turn machine, first launched at our ONE SHOW Technology Event in October, will be rubbing shoulders with a larger-capacity SMX 2100STB.

The 10” chuck DNX 2100SB, with its advanced Fanuc CUFOS control, is equipped with two built-in spindles, a12,000rpm B-axis milling spindle and a large-capacity (60 tool) ATC, and is ideal for machining small batches, quickly and without the need to undertake frequent tool change operations.

The SMX 2100STB is a well-established multi-tasking mill-turn machine from DN Solutions’ best-in-class SMX series. The 9-axis machine is equipped with two opposing spindles and a B-axis milling spindle (12,000rpm).

ZAYER machine tools

We’re showcasing a powerful, large-capacity and multi-tasking ZAYER ARION horizontal bridge-type milling machine on our stand. (The machine’s bridge and RAM configuration will be on show).

The box guideway ARION boasts 2000mm distance between columns, a 24kW/6,000rpm (high-torque) spindle and rapid rates (30m/min).

The machine’s rigid design and construction combined with its large capacity (i.e., X-axis = 3000mm, Y-axis = 2600mm, Z-axis = 1100mm), and choice of milling heads and control systems make it ideal for processing large and complex aerospace, automotive, rail, power generation components, and mould and die applications.

SYNERGi Automation Systems

SYNERGi automation systems deliver outstanding productivity and process efficiency benefits to customers, and can be integrated to DN Solutions’ lathes, machining centres and mill-turn machines to create fast and flexible automated manufacturing cells.

Powered by Mills’ proprietary SYNERGi software, these automation systems are constantly being developed, refined and improved to meet customers’ specific manufacturing and production requirements.

In a purpose-built AUTOMATION HUB on our stand, we will be showcasing the latest, innovative SYNERGi workpiece loading and unloading systems, as well as advanced (Next-Generation) 3D Machine Vision solutions that incorporate AI technology.

CNC Training Academy

In a separate part of our stand, the CNC Training Academy will be showcasing its latest digital twin technology solutions as well as the range of CNC (Fanuc/CUFOS, Heidenhain and Siemens) programmer and operator training courses available, including BobCAD-CAM training.

MACH 2026: Get yourself ‘back on track’

We are exhibiting a range of advanced and innovative technologies (machine tools and automation systems) on our stand at MACH 2026, and promise show visitors an exciting, thought-provoking and immersive experience.

Register now for MACH 2026.

Make sure you don’t miss out on seeing technologies on our Stand at MACH 2026 that are guaranteed to put you in pole position.

Register your attendance now by clicking the link below.