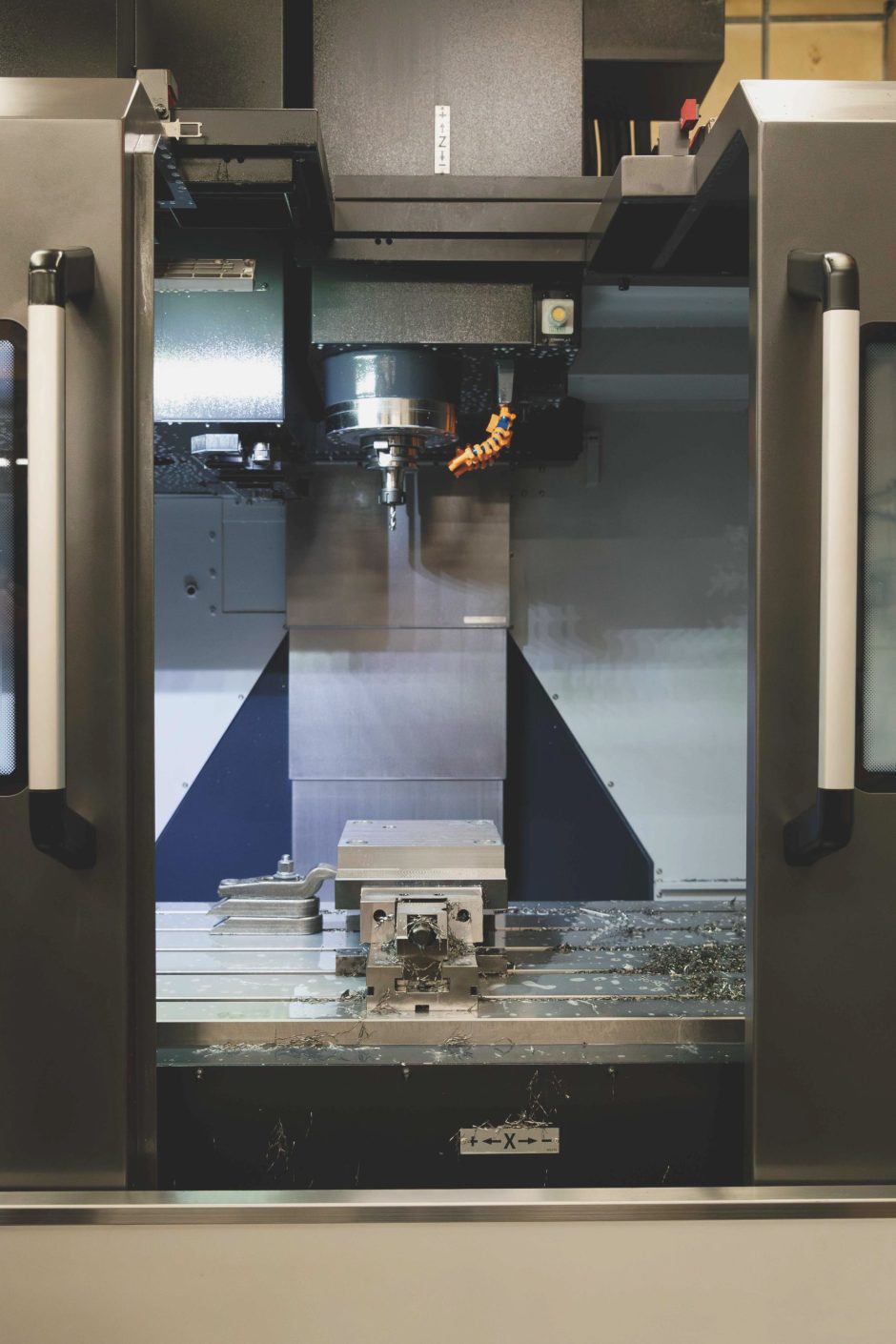

A recent investment in a new, large-capacity, heavy-duty vertical machining centre, equipped with a powerful gearbox-driven BT 50 spindle, is proving to be pivotal and transformative for Bronte Precision Engineering Ltd., a leading precision subcontract specialist based in Bradford, West Yorkshire.

The arrival of the new DN Solutions’ Mynx 6500/50 II machine in July 2025 has significantly increased and improved Bronte Precision Engineering’s in-house machining capacity and capabilities and, in just a few weeks, has helped the company improve its productivity and optimise its machining (milling) processes.

Mills CNC, the exclusive distributor of DN Solutions’ and Zayer machine tools in the UK and Ireland, has recently supplied Bronte Precision Engineering Ltd., a leading precision subcontract specialist, widely regarded and respected for its in-house gear cutting expertise and its proven large and complex part machining capabilities, with a new, heavy-duty 3-axis vertical machining centre.

The machine, a DN Solutions’ box guideway Mynx 6500/50 II, was installed at the company’s 16,000sq. ft. manufacturing facility in Bradford, West Yorkshire, in July 2025, and has replaced an older Daewoo Mynx 540 (BT 40) machining centre which, incidentally, was also supplied to Bronte Precision Engineering by Mills CNC way back in 2004.

Since being installed, the new Mynx 6500/50 II equipped with the latest Fanuc 0iMP control and a powerful, gearbox-driven 6,000rpm (BT 50) high-torque spindle, has been put through its paces machining a range of high-precision complex components, many of which were previously being machined on the, now replaced, Daewoo Mynx 540.

Background

Bronte Precision Engineering was recently acquired, in November 2024, by Huddersfield-based, B&B Engineering Ltd., a specialist precision engineering subcontractor renowned for its high-quality CNC machining and HVOF coating services and expertise, and boasting the latest advanced CNC machine tools, automated thermal spraying booths and a dedicated quality and inspection department, replete with an in-house metallurgical laboratory.

The acquisition of Bronte Precision Engineering by B&B Precision Engineering was the brainchild of entrepreneur and the (now) director of both companies, Steven Haigh.

“We acquired Bronte as a going concern because I could see definite synergies between the two companies and the opportunity for both to achieve exponential growth.

“I was confident that by bringing together the shared experience and expertise of our staff, and by combining the technical resources of both companies, we could increase our manufacturing capacity and capabilities and improve our flexibility and responsiveness, enabling us to take on additional, higher added value work and projects, and offer a better service to both new and existing customers.”

Steven Haigh, Director of Bronte Precision Engineering and B&B Precision Engineering

First things first

A few weeks after acquiring Bronte Precision Engineering, a comprehensive and systematic audit and review of the company, including the benchmarking of its (20+) CNC machine tools and manufacturing equipment, and its machining and manufacturing processes, was undertaken to identify process and system inefficiencies, and address actual and potential production bottlenecks and pinch-points.

One of the machines put under the microscope was the company’s Daewoo Mynx 540 – a 20-year old heavy-duty 3-axis vertical machining centre that, in truth, according to Steven Haigh “had seen better days.”

Daewoo Mynx 540

Bronte Precision Engineering’s (Fanuc-controlled) Mynx 540 was acquired in 2004, and over the last 20-years has been a front-line manufacturing resource for the company, machining a range of complex, high-precision parts, typically machined and supplied in small-to-medium sized batches, for its oil and gas, power generation, marine, rail, food processing, power transmission, steel processing, gearbox manufacturing and some EV customers.

Although the Mynx 540 was a rigidly-designed, box guideway machine, its relatively low-powered (15kW) BT 40 belt-driven spindle, in particular, meant that it was not the ideal solution for the fast and efficient rough and finish machining of many hard and difficult-to-machine materials (i.e., Inconels, Monel, Cast Iron, Stainless Steels, Duplex etc.), typically machined by Bronte Precision Engineering.

“The review of the Mynx 540 revealed that the machine was definitely ‘holding us back’.

“Part cycle times were overly long, and the machining processes employed were built around, and had to accommodate, the limitations of the machine, and were (as a consequence) impossible to optimise.

“It was clear that the Mynx 540 was a weak link in our production chain and that, to improve our performance, we needed to replace it with a new, high-performance, heavy-duty machining centre. As a consequence we did our homework, drew up a detailed new machine tool technical specification checklist and approached the market with our requirements.”

Steven Haigh, Director of Bronte Precision Engineering and B&B Precision Engineering

The new machine tool investment – imperatives

Bronte Precision Engineering’s machine tool checklist was comprehensive and identified a number of machine prerequisites. These included:

- A rigid machine with a box guideway construction

- A powerful, high-torque BT 50 spindle with through-spindle-coolant capability

- A large capacity worktable and machining envelope

- A generous-sized automatic tool changer

- In-process inspection/measurement (probing) systems

- The latest, advanced Fanuc control

The company approached Mills CNC and a number of other CNC machine tool manufacturers and suppliers, and ultimately, made the decision to invest in a new Mynx 6500/50 II based on the machine’s specification, its cost and availability, and the range of pre- and after-sales services provided by Mills.

Mynx 6500/50 II in action

Since being installed, the Mynx 6500/50 II has been (and is being) used to machine valve-type components (for subsea applications), made from Inconel castings, for a long-standing customer and manufacturer of high-performance industrial pumps.

Programmed off-line and machined in small batches, these parts are approximately 400mm x 300mm in size, involve long and intensive roughing and finishing operations to complete each part and are characterised by their tight ‘tied up’ tolerances and stringent surface finishes.

Part processing times with the new Mynx 6500/50 II are significantly faster (up to 50%) than those achieved using the Mynx 540…justifying and vindicating the new machine tool acquisition.

Mynx 6500/50 II – a closer look

Bronte Precision Engineering’s new Mynx 6500/50 II vertical machining centre is equipped with a high-torque, gearbox-driven BT 50 spindle (30kW/6000rpm/617N-m), a 30-tool servo-driven tool changer with 2.5 second tool-to-tool changeover time, and a 1400mm x 670mm worktable with a 1300kg maximum table load.

The machine was supplied with the advanced Fanuc 0iMP control, 20 bar through-spindle-coolant capability and Renishaw OMP 600 and OTS workpiece and tooling probing systems.

“The Mynx 6500/50 II is a powerful, accurate and flexible machining centre that, in just a few short weeks, has proved its worth.

“The machine’s rigidity, box guideway construction and powerful BT 50 spindle with through-spindle-coolant capability has enabled us to significantly improve our productivity and process efficiencies, and the ability to ramp up speeds and feeds and take more aggressive depths of cut have dramatically improved part cycle times.

“The machine is still being ‘bedded-in’, so to speak, but I am confident that once we are more familiar with all of its onboard technologies, we will be able to hit repeatable accuracies of +/- 0.05mm down to +/- 0.03mm on selected features.”

Steven Haigh, Director of Bronte Precision Engineering and B&B Precision Engineering

Bronte Precision Engineering’s investment in the Mynx 6500/50 II is both pivotal and transformative.

Pivotal in that the acquisition of the new machine is clear evidence of a decisive turning point in the company’s history and development, and transformative in that a commitment to continuous improvement and making strategic investments in new, advanced technologies (like the Mynx 6500/50 II) are the future direction of travel for both Bronte Precision Engineering and B&B Precision Engineering going forwards.