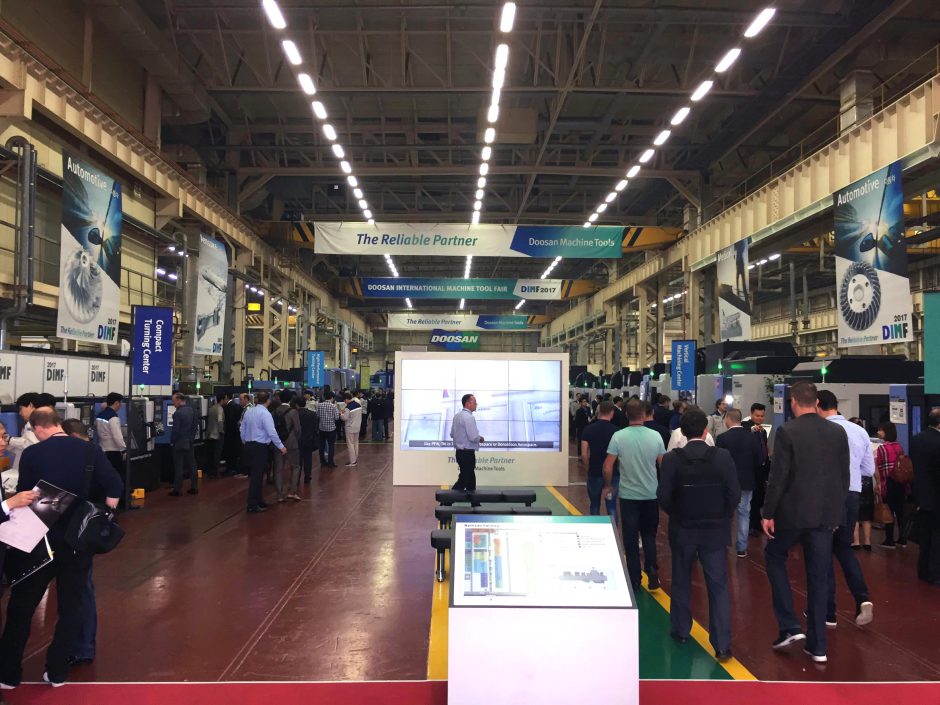

Doosan Machine Tools’ eleventh biennial DIMF Show (Doosan International Machine Tool Fair) held at the company’s production facilities in Busan, South Korea from 17th – 20th May 2017, proved to be a truly inspirational event with 5,700 Doosan dealers, distributors, academics and Doosan officials, and over 800 international visitors, attending the event.

In this article, Tony Dale, Technical Director at Mills reports on the latest DIMF Show and gives his insight on a cross-section of the new Doosan machines and machine upgrades that were on view – many of which will soon be available (from Mills CNC) to UK and Irish precision component manufacturers.

Comments Tony Dale:

“The latest DIMF Show was memorable for a number of reasons.

“Firstly it’s worthwhile stating from the outset that this year’s event was particularly impressive with some 80 Doosan machines (in total) being exhibited.

“This number comprised 26 new models from Doosan’s 5-axis machining centre, large-capacity lathe, big horizontal and horizontal boring machine and multi-tasking, multi-axis mill-turn centre ranges.

“In addition to showcasing these new machines – DIMF 2017 was also the venue where Doosan’s latest Industry 4.0 ’SMART FACTORY” and automation solutions were exhibited.

“Doosan is one of the largest global manufacturers of CNC machine tools – and the sheer size, scope and scale of this year’s DIMF Show reinforced the company’s market-leader position.

“Although DIMF took place at Doosan’s South Korean Namsan and Sungju facilities, the event is definitely not a parochial event – as many of the new and upgraded machines and technologies on view will soon become available to manufacturers across the world via Doosan’s subsidiaries and its global network of distributors and dealers.

“Indeed one of the major reasons why we here at Mills CNC attended the Show was to identify the new and upgraded Doosan machines that will be promoted and stocked at our Technology Campus in Leamington in the near future.”

DIMF 2017 Highlights

5-axis machining centres:

“DIMF provided the ideal venue for Doosan to showcase two latest additions to its already impressive 5-axis machine tool line-up. These machines – the DVF 5000 and DVF 8000 – are available with a choice of controls (Fanuc, Siemens and Heidenhain) and provide manufacturers with full 5-axis simultaneous machining capability.

“The machines are ‘automation-ready’, and can be supplied with a range of different automatic pallet change systems that increase their productivity potential.

Horizontal machining centres:

“Doosan horizontal machining centres are recognised for their performance and productivity-enhancing features. At this year’s DIMF Show a number of horizontal machining centres were exhibited and included the launch of two new high-speed, high-accuracy machines – the NHP 4000 and NHP 5000.

“Both machines feature a rigid design and build, and are equipped with powerful high-torque spindles (up to 37kW/20,000rpm/308Nm). The machines provide users with 1g acceleration/deceleration and 60m/min rapid rates on their X-,Y- and Z-axes.

Horizontal fixed head lathes:

“No DIMF Show would be complete without specific attention being focused on Doosan’s new Lynx and Puma lathe ranges.

“New additions and upgrades to Doosan’s Lynx range of lathes included the introduction of 8” chuck models (Lynx 2100Y/LY/LSY) with Y-axis capability, and the 10” chuck/81mm bar capacity Lynx 2100LC – all available with Fanuc or Siemens controls.

“New Puma lathes were also the ‘centres of attraction’ at DIMF and amongst the many highlights were the new 10” chuck Puma 2600 (Y-axis) Mark II machines.

“The new Puma 2600Y/LY/SY/LSY lathes feature sophisticated thermal compensation sensor technology which, in combination with their rigid design and improved spindle bearing structure, deliver guaranteed accuracies, even during continuous use.

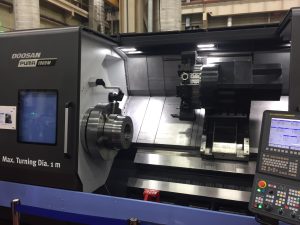

“With its powerful, high torque spindle and rigid design, the Puma 1000 is Doosan’s largest horizontal lathe and is ideal for heavy-duty machining operations.

Multi-axis machines

“Doosan’s new multi-axis machines were out in force at DIMF 2017 with pride of place reserved for a new range of SMX mill-turn machines equipped with lower turrets.

“The SMX range, already available in the UK, has now been joined by two new models – the 10”chuck SMX 2600ST and the 12” chuck SMX 3100ST.

“These new machines feature Doosan’s orthogonally-designed (300mm) Y-axis), and are equipped with 12 station lower turrets for improved manufacturing flexibility and productivity.

“The last new Doosan machines worthy of special mention that were launched at DIMF were the Puma TW2100 GL – a 8” chuck (6” chuck option) twin-spindle horizontal turning centre with an integrated Gantry Loader, and the large-capacity Puma V8300M (up to 24“ chuck) with its uniquely-configured and versatile Capto C6 ATC.”

Summary

DIMF 2017 was a truly impressive event.

Although the Show is over its impact (due to the many new technologies introduced) will be felt around the world for months and years to come and Mills will be showcasing a number of the machines launched at DIMF at its ‘Strokes of Genius…LIVE” Open House taking place at its Campus facility in October (18th and 19th) 2017, and from its stand at the MACH 2018 show.