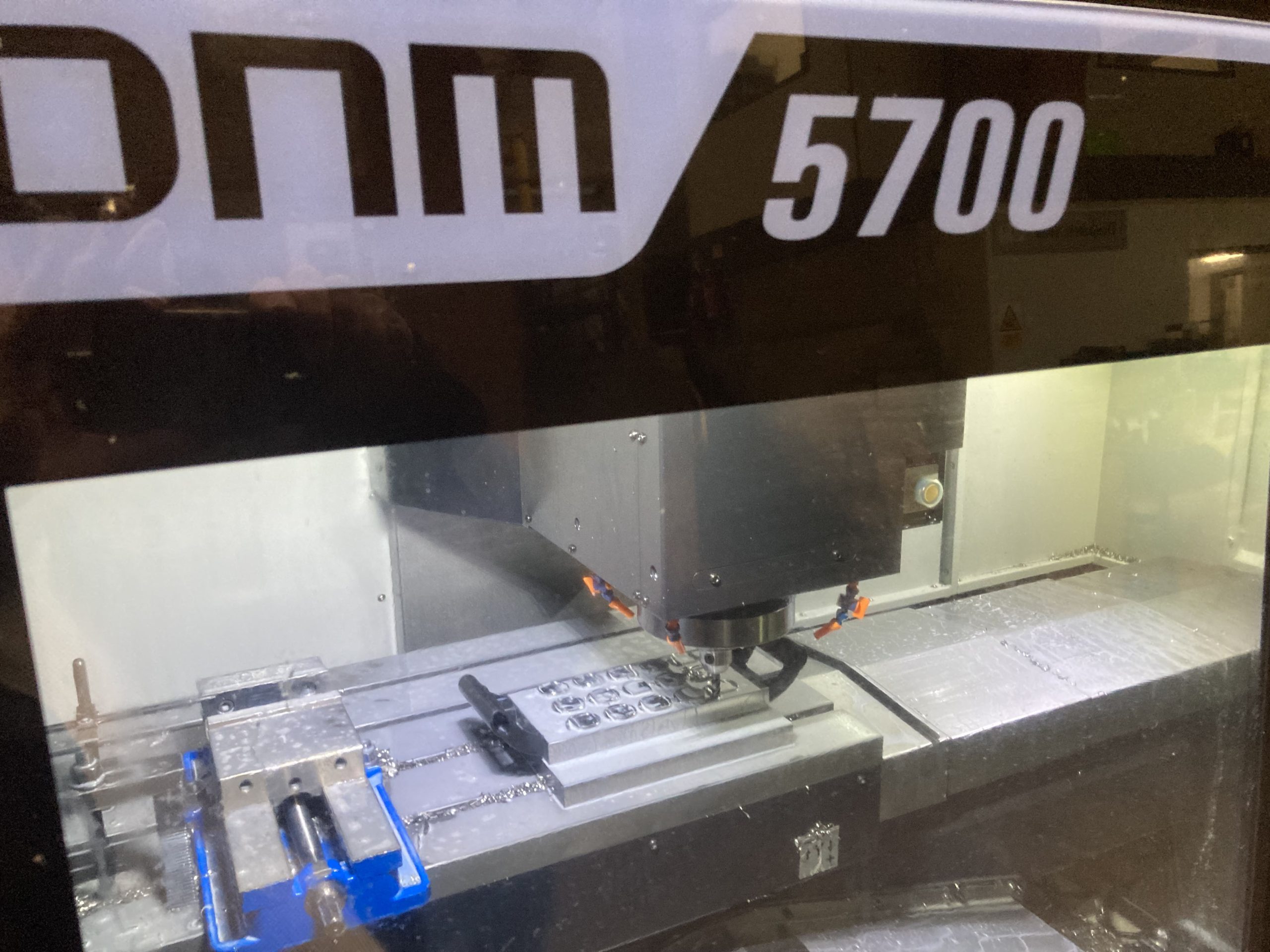

NextGen Precision’s investment in a new Fourth-Generation DNM 5700 vertical machining centre from Mills CNC has significantly increased and improved the company’s machining capacity and capabilities.

The new machine, in just a few weeks, has proved its worth dramatically reducing part cycle times, by up to 60% in some instances, and improving turnaround times – both of which have helped the company improve and strengthen its supply chain position with customers.

Mills CNC, the exclusive distributor of DN Solutions’ and Zayer machines tools in the UK and Ireland, has recently supplied NextGen Precision Ltd., a leading precision subcontract specialist based in Blackburn, Lancashire, with a new high-performance 3-axis vertical machining centre.

The machine, a DN Solutions’ Fourth-Generation DNM 5700 equipped with the advanced Siemens 828D control, was installed at NextGen Precision’s machine shop in July 2025, and is the first machine tool the company has acquired from Mills CNC in its 44-year history.

NextGen Precision – background

NextGen Precision is a successful family-owned business that employs five members of staff.

The company is committed to continuous improvement and, as such, regularly invests in its people, in its plant and equipment, and in its systems and processes.

As part of its ongoing improvement programme, NextGen Precision is currently undergoing a strategic review and revamp of its machine shop in order to a) improve and strengthen its supply chain relationships and facilitate organic growth opportunities with existing customers in the highly-regulated aerospace, security and nuclear sectors etc., and b) to win new business from new customers.

A recent management restructure, implemented at the start of 2025, has seen the company, now under the direction of brothers, Stephen and Mark Fairbrother, revitalise its machining operations and processes with a clear focus on Lean Manufacturing and Six Sigma principles and methodologies.

It is this commitment to improving process efficiencies, quality and customer satisfaction, by streamlining workflows and using statistical analysis to solve production issues, that not only helps NextGen Precision differentiate itself from its competitors, but also provides the solid foundation for the company’s future growth.

New machine tool investment decision – catalyst

To improve productivity and maintain its competitive edge, NextGen Precision systematically monitors, analyses and benchmarks the performance of its machine tools and process efficiencies in order to identify actual and potential production bottlenecks and pinch-points.

In the Spring of 2025, a new customer operating in the security sector approached NextGen Precision to discuss its immediate and future requirements for high-precision components supplied in large volumes, typically up to 2500-off per month.

“Although the new business was clearly welcomed, we could see that the nature of the new machining contract, and the part quantities involved, would put our existing machining capacity and capabilities under pressure.

“Initially, we thought we could handle the order with two of our older milling machines but, although these machines could hit the tight tied up tolerances required, they simply couldn’t machine the quantity of parts required fast enough to meet the customer’s delivery schedules.

“As a result, we made the decision to invest in a new high-performance machining centre, and run it in tandem with one of the older machines.”

Stephen Fairbrother, Co-Owner and Director of NextGen Precision

Rather than just acquiring new, ‘like for like’ milling capacity, NextGen Precision, with what little time it had available before the new contract started, gave itself some breathing space to consider both its immediate and future milling machine tool capacity and capability requirements.

Investment decision – imperatives

NextGen Precision’s reputation is built on delivering high-quality, competitively-priced machined components, made from a range of different materials (i.e., from aluminium alloys through to Stainless Steel 316, Inconels, Stellite and other exotics etc.), and deliver them on time, every time.

The company has spent, and continues to spend, considerable time and resource designing and developing robust machining processes that can achieve tight geometrical tolerances, typically down to 0.01mm on and across all machined features, and meet stringent surface finish requirements (i.e., down to Ra 0.4um).

“We decided to future-proof the investment and make sure that the new machine tool we acquired was capable of meeting our own, and our customers’, immediate and future high accuracy, guaranteed repeatability and fast turnaround demands.

“As a consequence, before we approached the market to talk to individual machine tool suppliers, we drew up a detailed checklist for the new machine.”

Mark Fairbrother, Co-Owner and Director of NextGen Precision

The checklist included the following ‘must have’ features:

- A rigid design and construction that would a) help minimise vibration and deflection to ensure high part accuracies, superior surface finishes and longer tool life, and b) optimise processing speeds by enabling faster speeds and feeds to be employed and more aggressive depths of cut to be taken.

- A powerful, high-torque, directly-coupled spindle capable of achieving high material removal rates (MRRs) and super-fine finishing, as well as being flexible enough to machine a wide range of different materials.

- A good-sized worktable capable of machining large workpieces and/or multiple smaller components in one set up.

- A generous-sized tool changer, with quick changeover times, to facilitate the fast and efficient machining of complex parts with intricate features without the need to stop the machine to undertake retooling operations.

Although NextGen Precision had not previously invested in a DN Solutions or Doosan machine from Mills CNC, director Stephen Fairbrother had a positive experience of working with/on them as a toolmaker in the past.

As a consequence, Mills CNC was one of the machine tool suppliers NextGen Precision approached with its requirements.

“We visited Mills’ facility in Leamington where we were introduced to the Fourth-Generation DNM 5700. We liked the look of the machine from the outset.

“In addition to the machine’s build, its spindle power and configuration, and its worktable and tool changer, we were informed that a new DNM 5700 also came supplied with roller-type LM guideways, for smooth and efficient operation and long-term accuracy, and an innovative all-grease lubrication system that reduced lubrication frequency and eliminated the need for oil-skimmers.”

Stephen Fairbrother, Co-Owner and Director of NextGen Precision

To ensure that the DNM 5700 perfectly matched NextGen Precision’ requirements, the company also enquired about:

- The inclusion of tool and workpiece probing systems for in-process measurement and tool breakage detection

- An auto-door facility to enable the integration of an industrial robot, cobot or pallet-change system to be retro-fitted to the machine at a later date

- The advanced, flexible and conversational Siemens 828D control which would make machine tool programming and operation easier and faster.

“We liked and valued Mills’ approach.

“Not only could they ‘customise’ the DNM 5700 so that it would meet our immediate and future requirements, but they could also arrange a flexible finance solution via their Mills CNC Finance operation, and deliver and install the machine from stock in double-quick time.

“As a consequence, we placed the order for the new DNM 5700.”

Stephen Fairbrother, Co-Owner and Director of NextGen Precision

DNM 5700 – in action

Since being installed in July 2025, NextGen Precision is using the DNM 5700 to not only machine and supply large quantities (i.e. 2500 parts per month) of high-precision parts, machined in batch sizes of 15-off, for its new security industry customer, but also to develop and refine the machining processes currently employed to machine the parts to further optimise processing speeds, repeatability and reliability.

The parts being machined are small (i.e., 50mm diameter), and are made from Stainless 316. They are machined from solid billet, using small diameter tools and high-pressure coolant, to tight, exacting and non-negotiable tolerances (i.e., 10 microns) and, using Fusion CAD/CAM, are machined to completion using innovative fixtures designed and manufactured in-house by NextGen Precision.

(Incidentally, the cycle time currently required to process a batch of 15 parts on the new DNM 5700 is 105 minutes compared to 270 minutes on NextGen Precision’s older milling machines.)

“We are working closely with Mills’ applications’ team to develop and refine the machining process in order to achieve and maintain a high CPK value.

“Once we have done this, which isn’t that far off, we will have a process that is not just repeatable but one that can be transferred to new Siemens-controlled DNM 5700 machining centres that we’re looking to acquire in the not-too-distant future.”

Mark Fairbrother, Co-Owner and Director of NextGen Precision

DNM 5700 – a closer look

DN Solutions’ DNM 5700 vertical machining centres are proven performers and are amongst Mills’ best-selling, small to medium sized, CNC milling machines.

The model installed at NextGen Precision was equipped with a powerful, high-torque 18.5kW/ 12,000rpm/ 118N-m directly-coupled spindle, a large worktable (1300mm x 570mm) with a 1000kg table load, roller-type LM guideways, a 30-tool ATC, a large coolant tank (430L) and the, previously mentioned, advanced Siemens 828D control with conversational ShopMill part programming capability.

The machine was also supplied, in addition to its probing systems, with a FilterMist oil mist extraction unit and a swarf conveyor and bin.

Summary

NextGen Precision’s investment in a new Fourth-Generation DNM 5700 provides real and tangible evidence of the company’s ambitions to transform the productivity and performance of its machine shop, ramp up its production capacity and improve its process efficiencies.

“We are delighted with the new DNM 5700 machine. The machine is fast, accurate and flexible, and we have developed a great working relationship with Mills CNC as well.”

The recent investment in the DNM 5700 from Mills CNC may well be the first DN Solutions’ machine acquired by NextGen Precision, but it certainly looks like it will not be the last.

Stephen Fairbrother, Co-Owner and Director of NextGen Precision