2025 is already proving to be a memorable, stand-out year for leading precision motorsport subcontract specialist, Northants Precision.

In addition to acquiring two more DN Solutions’ Lynx 2100 lathes from Mills CNC, the company has successfully completed its relocation to larger and more modern premises, increased its headcount and, helping to facilitate all of the above, has secured new machining contracts and both strengthened and elevated its position within a number of its customers’ supply chains.

Underpinning the company’s growth and success is Northants Precision’s commitment to continuous improvement, and its strategic and timely investment in its people, in its plant and equipment and in its processes and systems.

Led by owner and managing director, Daniel Green, Northants Precision is a company that never rests on its laurels and, with six high-performance Lynx lathes now at its disposal is, after only five years, justifiably regarded as one of the UK’s most progressive and dynamic SMEs operating within the motorsport supply chain.

Mills CNC, the exclusive distributor of DN Solutions’ and Zayer machine tools in the UK and Ireland, has recently supplied leading motorsport precision subcontract specialist, Northants Precision Ltd., with two new DN Solutions’ Lynx lathes.

The machines, an 8” chuck, long-bed Lynx 2100LMB with driven tooling and a 6” chuck, 2-axis Lynx 2100A, were installed at the company’s new, modern and spacious 3500sq. ft. manufacturing facility in Kislingbury, Northampton, in January 2025 and June 2025 respectively.

The new machines have been positioned in close proximity adjacent to four, previously acquired, Lynx lathes – a Lynx 2100B (2022), a Lynx 2100MB (2021), a Lynx 2100LMB (2021) and an older (10 year old) Lynx 220LSY.

Together, these six Fanuc-controlled machines, three of which have driven tooling capabilities, provide Northants Precision with a flexible and formidable in-house turning and milling resource, ideal for meeting the accuracy needs and fast turnaround demands of its motorsport customers.

Since being installed, the new Lynx lathes have gone ‘straight into action’ machining a range of small, complex and high-precision engine, chassis, sub-frame and gearbox components for the company’s F1, WEC (World Endurance Championships), WRC (World Rally Championship) and supercar customers.

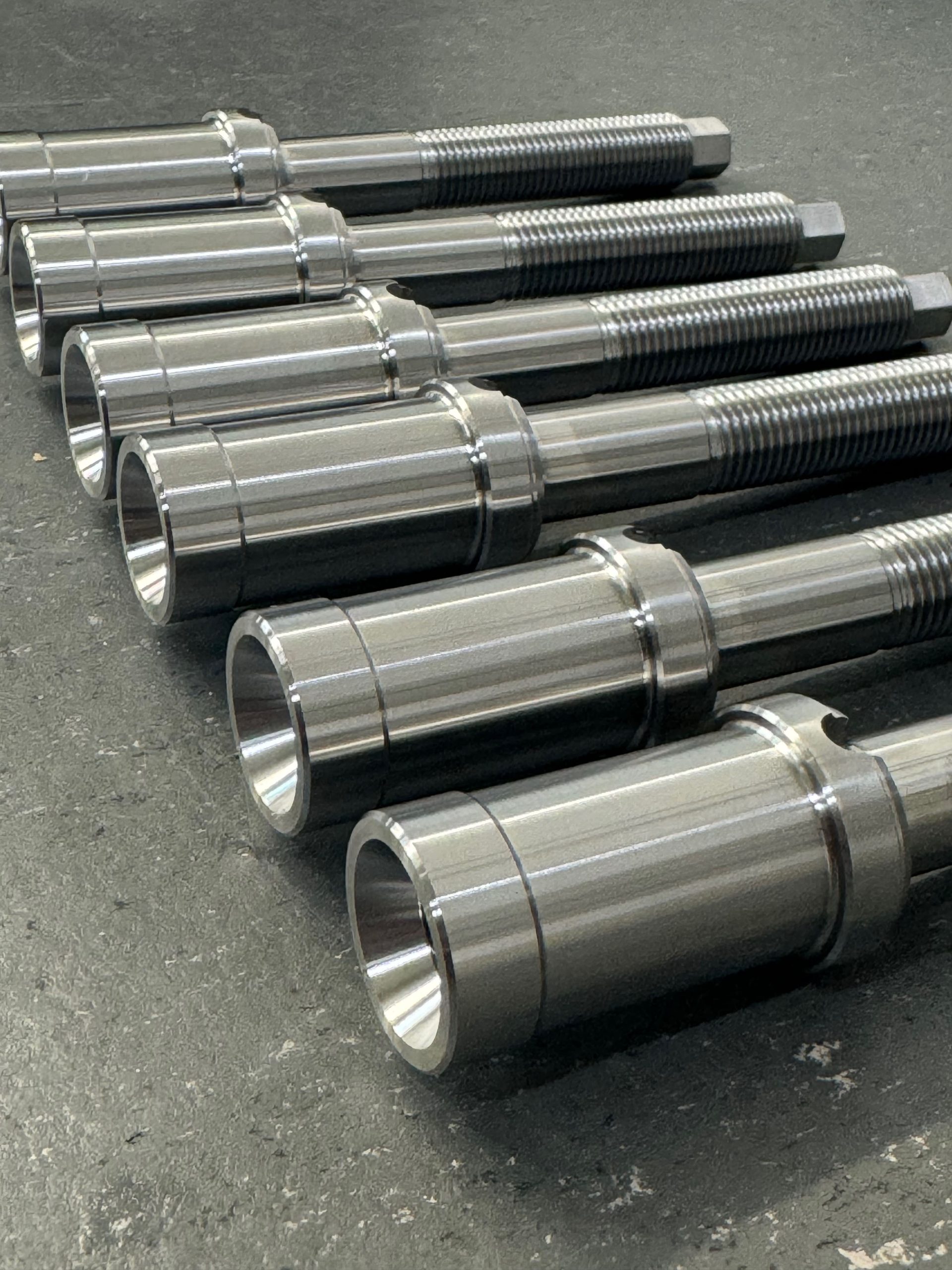

Parts machined on the new Lynx lathes, and all of the company’s Lynx lathes for that matter, are small and are typically round and/or cylindrical in shape.

To the layman, a significant number of these parts could be, disparagingly, described as being nothing more than washers, nuts, bolts and top hats but, to those in the know, there is a lot more to them than that.

Characterised by their closed, tight tolerances (i.e., typically +/- 5 microns on specific features and 0.01mm or 10 micron flatness) and by their stringent, super-fine surface finish requirements, both pre- and production parts are machined in small-to-medium batches from solid bar stock with heat-treated stainless steels (i.e., 13-8PH and MP35N), titanium 6242/6246 alloys and (some) aluminium being the predominant materials processed.

Part cycle times are short, from just a couple of minutes up to 10 minutes at the top end and, to ensure accuracy, concentricity, flatness and fast processing speeds, parts are held securely in position using Hainbuch collet chucks.

“Machining and supplying hundreds and, sometimes, thousands of identical high-precision and performance-critical parts from hard and difficult-to-machine materials to exacting quality standards is commonplace for us.

“But to be able to do this all the time, every time, requires reliable, high-performance machines and proven and efficient CAD/CAM, machining and inspection processes.

“We have invested significant resources to ensure we have all of the above in place.”

Daniel Green, Owner and Managing Director at Northants Precision

The two new Lynx lathe investment – rationale

Northants Precision regularly monitors and benchmarks its performance to identify actual and potential production pinch points and bottlenecks, and address them before they become problematic.

The company’s continuing success in securing small part machining contracts from new and existing customers, including recent contracts won directly with F1 racing teams, caused Northants Precision at the end of 2024, and again during Spring 2025, to review its in-house machining capacity and capabilities, and ultimately place orders for two new machines.

“The F1, and the motorsport sector in general, is demanding and challenging. You always have to be ‘on the top of your game’ and be able to constantly hit customers’ quality and lead time requirements from day one. Failure to do so quickly tarnishes your reputation and means that your days working as a supplier in the sector are numbered.

“Our previous positive experiences with DN Solutions’ (previously Doosan) Lynx 2100 lathes and Mills CNC’s pre- and after-sales services and support (i.e., Mills CNC Finance etc.), meant that, on both occasions, we made Mills our ‘first port of call’, and ultimately invested in the new Lynx 2100A and the new Lynx 2100LMB.

“Both machines, as intended, have significantly strengthened our in-house capacity and capabilities, making us more competitive and allowing us to take on more work.”

Daniel Green, Owner and Managing Director at Northants Precision

A typical machined part: engine housing washer component

Made from 10mm diameter pre-cut titanium bar stock supplied in 42” lengths, these parts are machined to completion in medium-sized batches (i.e., 600-off) using two of Northants Precision’s Lynx 2100 lathes that have been positioned opposite one another to create a flexible manufacturing cell, operated and controlled by one member of staff.

Front-end ID and OD turning operations are undertaken on a Lynx 2100 (two-axis) lathe where the use of an independently-sourced bar puller, located in the machine’s turret, helps deliver a reliable and repeatable process and ensures continuous production.

Following first operations, which take approximately 2 minutes per part to complete, the semi-finished parts are then individually and manually loaded into the Lynx 2100LM for back-end part processing; this effectively requires the machining of an angled groove/chamfer on each part, taking approximately 30 seconds to complete.

Despite the small size of each component and relatively large batch numbers involved, all parts undergo rigorous inspection to ensure their accuracy and specification compliance.

“We strive for excellence across the board.

“Despite lots of moving parts, our machine shop works like a well-oiled machine. Everything we do, from our in-house CAD/CAM, machining and inspection operations through to any and all out-sourced pre- and post-machining processes we require (i.e., heat treatment, thread rolling, EDM, surface treatments etc,), are integrated, and are carefully and meticulously planned and controlled.”

Daniel Green, Owner and Managing Director at Northants Precision

Lynx 2100A and Lynx 2100LMB – a closer look.

Lynx lathes are flexible, fast, accurate and reliable. They are equipped with powerful, high-torque spindles, servo-driven turrets, rigid roller-type LM guideways, hydraulic tailstocks and the advanced Fanuc iPlus control with a 15” touchscreen iHMI.

The Lynx 2100A has a maximum turning diameter of 350mm and a maximum turning length of 330mm, and features a 15kW/6000rpm spindle and a 12-station turret. The machine was supplied to Northants Precision with an auto tool setter and a FilterMist extraction unit.

The Lynx 2100LMB has a maximum turning diameter of 300mm and being a long bed model, has a maximum turning length of 510mm. The machine is equipped with a 15kW/4500rpm spindle, a 12/24-station turret and 6000rpm driven tooling capabilities and, as part of the deal, was supplied with an auto tool setter and an extraction unit.

Improvements across the board

Other technology and process improvement investments

In addition to investing in two new Lynx 2100 lathes, Northants Precision has further strengthened its in-house machining capabilities by acquiring a used sliding head lathe with an integrated bar feeder, a used 3-axis machining centre and a 3D printer essentially used for producing fixtures and tooling.

“The sliding head lathe is being used for high-volume part production, specifically for an automotive customer. Integrated with a bar feeder that enables it to run unattended, overnight and over the weekends, we can machine and supply the customer with up to 20,000 – 30,000 parts per month.”

Daniel Green, Owner and Managing Director at Northants Precision

The investment in the used milling machine was made to help out the company’s small turned part processing operations.

“Although our focus is on machining small turned parts there are occasions where we need access to a separate milling machine. Having the ability to mill specific features on mill-turned parts using a dedicated machining centre is often more efficient and effective than machining them on one of our multi-tasking Lynx 2100 lathes with driven tooling.

“Having this flexibility was the rationale behind the 3-axis milling machine investment.”

Daniel Green, Owner and Managing Director at Northants Precision

To be successful in the motorsport sector, production process efficiency (i.e., from quotation and stock control through to all aspects of production, packaging and invoicing) is critical.

Northants Precision’s investment in a PSL Datatrack modular production control system and, more recently, the introduction and use of a tool vending machine on the shop floor, have significantly helped the company achieve real time productivity gains and monitor its operations more effectively – increasing process efficiencies and reducing waste etc.

Headcount increases

Northants Precision currently employs five members of staff – two of which are recent additions.

All machine shop staff are experienced, multi-skilled and wear a number of hats. All operate and tend more than one machine with one staff member being also responsible for the company’s inspection operations.

“We are a close knit team, we rely on each other and have the same ‘continuous improvement and commitment to quality’ mindset which has proved to be a winning formula.”

Daniel Green, Owner and Managing Director at Northants Precision

New premises

Northants Precision completed its relocation to new premises in January 2025.

The new facility is larger and, with its new painted floor, newly-constructed mezzanine and offices, and efficient machine shop layout replete with eight machine tools, certainly looks the part.

The relocation occurred during one of the busiest motorsport periods (December to February) and for a time, whilst the new facility was being prepared and finished, the company was effectively operating from two sites.

“It wasn’t ideal, but we just had to bite the bullet and get on with things.”

Daniel Green, Owner and Managing Director at Northants Precision

The new facility is modern and spacious, and motorsport customers, new and old, cannot fail to be impressed with the great strides made by Northants Precision.

Summary

Motorsport is a demanding sector with quality and lead times being non-negotiable.

To meet these challenges, Northants Precision has continued with its investment in new, advanced DN Solutions’ machine tools from Mills CNC.

The company’s in-house turning capabilities, which now includes three machines with driven tooling capabilities, have been instrumental in helping Northants Precision strengthen its position within numerous customers’ supply chains and acquire new work as a consequence.

With the ability to multi-task being a key attribute and skill for any SME, let alone one that is focused (virtually) entirely on motorsport, Northants Precision has, over the last six months, simultaneously and successfully kept a lot of balls in the air – not only improving its in-house machining capacity and capabilities, but also completing a company relocation and increasing its headcount too.

“It’s been a challenging time but, now we’re through the other side, it’s definitely been worth it and everything we’ve done is now paying dividends.”

Daniel Green, Owner and Managing Director at Northants Precision