Why Choose an Industrial Robot?

Benefits of Industrial Robots

There are many advantages and bottom line benefits to be gained from introducing industrial robots into a production/manufacturing process –

- Improved efficiency

- Higher quality

- Increased productivity

- Improved flexibility etc.

Mills CNC’s SYNERGi Cells

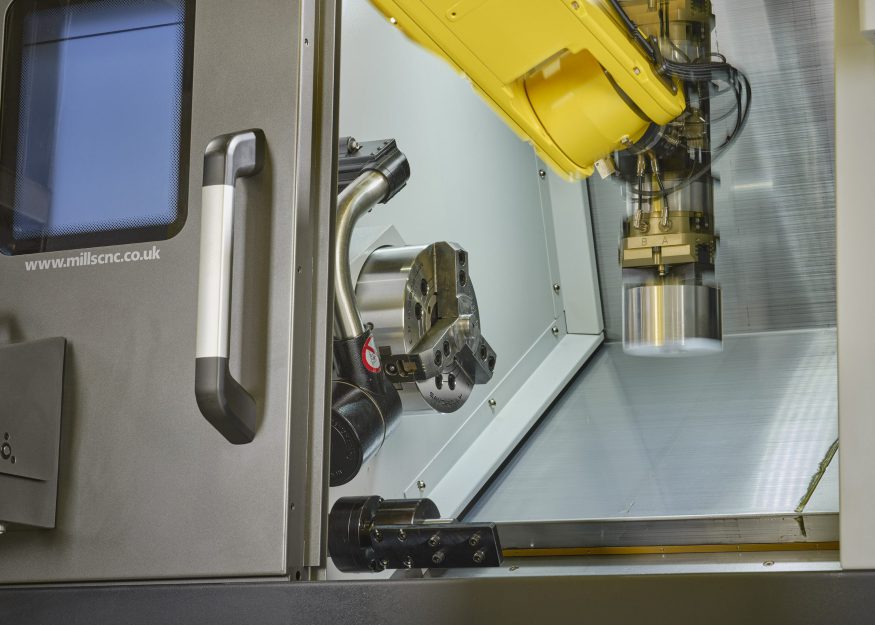

In collaboration with a number of select technical partners, Mills CNC have designed and developed a market-leading automation solution called SYNERGi automated manufacturing cells.

SYNERGi systems (SYNERGi Premier and SYNERGi Sprint) comprise industrial robots, innovative work loading/unloading stations, different end-effectors (including vision systems), laser floor scanning technology, industrial caging and our own, proprietary SYNERGi software to create flexible, state-of-the-art manufacturing cells that revolutionise productivity, quality and performance.

SYNERGi cells represent applied and smart Industry 4.0 technology at its best.

SYNERGi Systems

Versatile and flexible automated manufacturing cells enabling Industry 4.0 and the factories of the future.

SYNERGi Premier

SYNERGi Premier systems can be integrated with a DN Solutions / Doosan lathe, machining centre or mill-turn machine. They can also be integrated with more than one DN Solutions / Doosan machine.

SYNERGi Sprint

Following the successful introduction of our SYNERGi Premier and Classic cells we have now launched our new SYNERGi Sprint automated cells for DN Solutions / Doosan lathes and machining centres.

Industrial Robots in Action

Why Choose Mills CNC?

Delivery and Installation

Because SYNERGi systems aren’t plug and play automation systems, delivery and installation is tailored to your unique solution.

Servicing and Support

Mills CNC provide bespoke servicing and support for our SYNERGi systems, including regular maintenance and sourcing spare and replacement parts.

Finance

Mills CNC Finance provide a wide range of finance options for your SYNERGi system that are tailored to your unique requirements.

Training and Software

We help manufacturers get the best and Mills offer everything you need to manage and operate your SYNERGi system, including training and software.

Interested In Industrial Robots? Get In Touch

Contact the team at Mills CNC to find out about our SYNERGi automation systems, or to get more details about industrial robot solutions.