All End Of Arm Tooling

Showing 8 products

- No external cables

- Adjustable force and stroke

- Absolute width read out in MM

- No external air supply

- No external cables

- Dual grip with two individual vacuum channels

- Grabs with Ghecko style adhesive

- Picks up flat objects without air system

- Can lift solid or porous objects

- No external cables

- Adjustable force and stroke

- Automatic tool center point (TCP) calculation

- Comprehensive software package

- Easy to use graphical user interface (GUI)

- Preprogrammed force sensing applications

- No external cables

- Adjustable force and stroke

- Absolute width read out in mm

- Easy and fast change of tools

- Redundant locking mechanism

- Up to 10kg payload

- Gripper with F/T sensor at the fingertips

- Detects workpiece using proximity center

- Detects risk of slipping before it happens

Why choose Mills CNC

Why choose Mills CNC

Mills CNC are much more than just a Doosan distributor, our services and support ensure that you can get exactly what you need from financing options to training for your team.

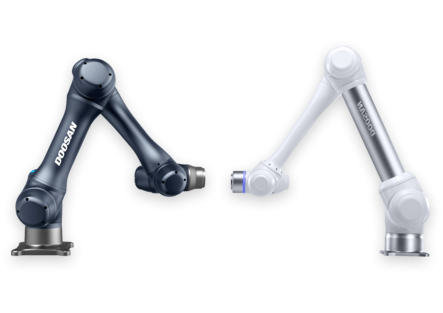

There are two types of automation solution available from Mills CNC – Collaborative Robots, and Industrial Robots.

Collaborative Robots

A cobot, or collaborative robot, is a robot intended for direct human/robot interaction within a shared space, or where humans and robots are in close proximity. Cobot applications contrast with traditional industrial robot applications in which robots are isolated from human contact.

Cobot safety relies on lightweight construction materials, rounded edges, and inherent limitation of speed and force, and on the use of sensors and software that ensures safe operation.

Industrial Robots

An industrial robot is a robot system used for and in manufacturing. Industrial robots are automated, programmable and capable of movement on three or more axes.

Typical applications include machine tending, welding, painting, assembly, disassembly, pick and place operations, packaging and labelling, palletising, product inspection, and testing; all accomplished with high endurance, speed, and precision.

Our industrial robot systems have been branded SYNERGi systems and are delivered as flexible automated manufacturing cells.

Get in touch

If you’d like to find out more about any of our machines, if you’d like a brochure or want to book a demo, then we’d love to hear from you. Whether you’re looking for a specific machine, or want to know more about our turnkey or automated solutions, Mills CNC can help.