Puma 700 II Series

DN Solutions (formerly Doosan) Puma 700 lathe series

Puma 700 II Series Description

DN Solutions Puma 700 lathes are popular amongst component manufacturers looking for a powerful and reliable turning solution.

These lathes have a large chucking capability (24” chuck standard) and bar work capacity (164mm bar diameter), and have been designed to machine large and heavy work-pieces.

Puma 700 machines are used extensively in the power generation, oil and gas and large automotive sectors, and deliver outstanding part accuracies, surface finishes and process reliability.

Puma 700 lathes with long beds (up to 5 metres), driven tools (11kW/3000rpm) and Y-axes (+/- 100mm) are all available.

Product specifications

Puma 700XLY II

CNC Horizontal Single Turret Lathes

- 24” chuck

- 164mm bar diameter

- 55kW/1500rpm spindle

Puma 700XLM II

CNC Horizontal Single Turret Lathes

- 24” chuck

- 164mm bar diameter

- 55kW/1500rpm spindle

Puma 700XL II

CNC Horizontal Single Turret Lathes

- 24” chuck

- 164mm bar diameter

- 55kW/1500rpm spindle

Puma 700M II

CNC Horizontal Single Turret Lathes

- 24” chuck

- 164mm bar diameter

- 55kW/1500rpm spindle

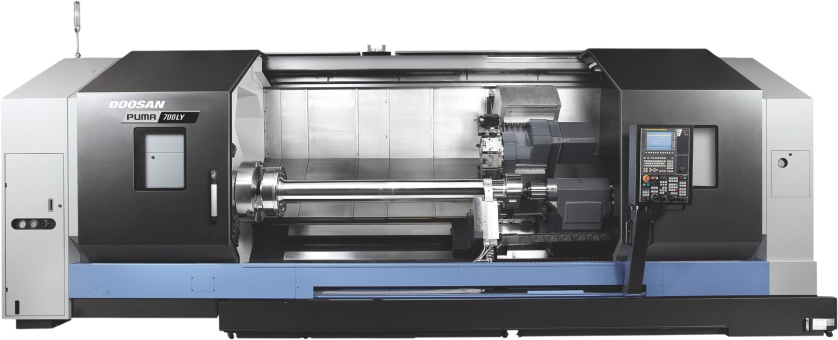

Puma 700LY II

CNC Horizontal Single Turret Lathes

- 24” chuck

- 164mm bar diameter

- 55kW/1500rpm spindle

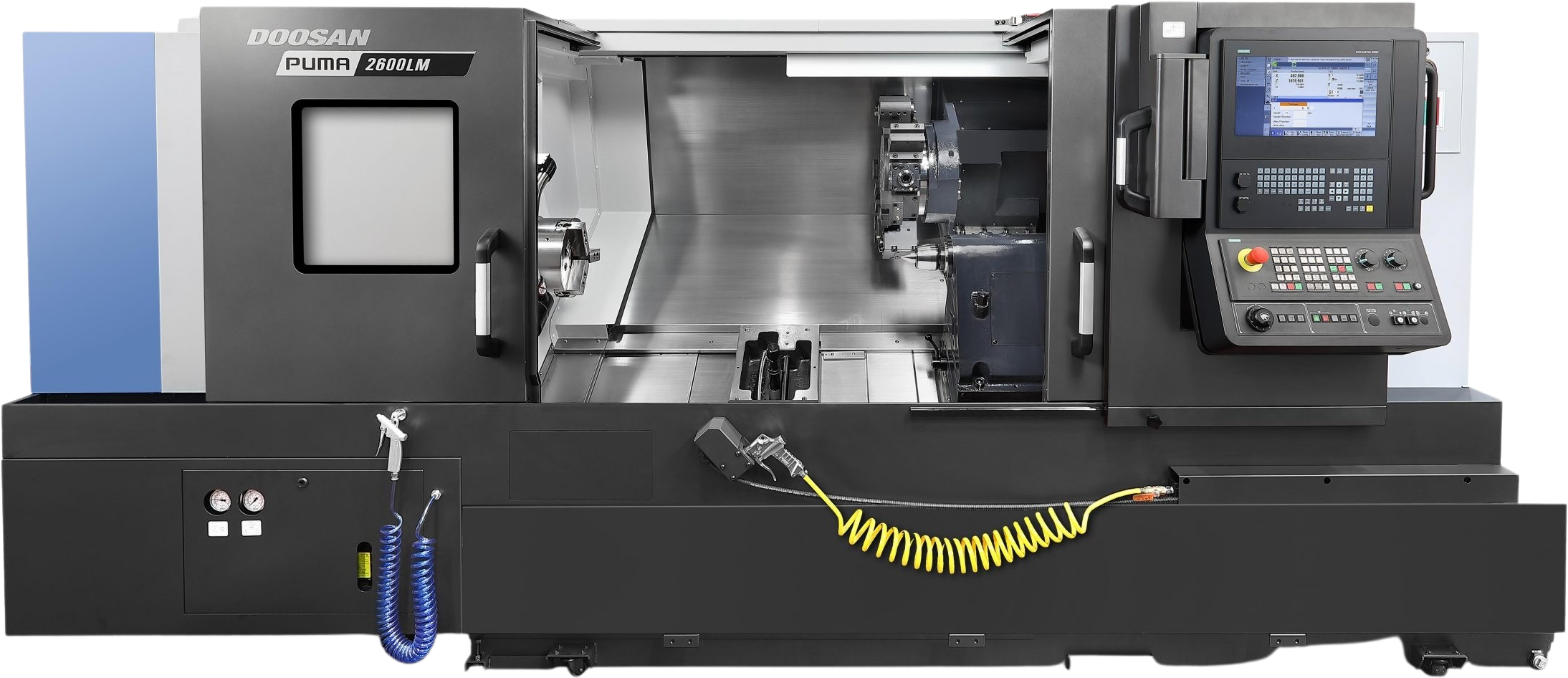

Puma 700LM II

CNC Horizontal Single Turret Lathes

- 24” chuck

- 164mm bar diameter

- 55kW/1500rpm spindle

Puma 700L II

CNC Horizontal Single Turret Lathes

- 24” chuck

- 164mm bar diameter

- 55kW/1500rpm spindle

Puma 700 II

CNC Horizontal Single Turret Lathes

- 24” chuck

- 164mm bar diameter

- 55kW/1500rpm spindle

Related Case Studies

Everything’s going according to plan

Horizontal Single Turret Lathe

Market-leading composite manufacturer Tufcot, is an innovative company with ambitious plans for the future. This includes the implementation of a continuous improvement programme, enhanced by its investment in a new large-capacity, multi-tasking lathe from Mills CNC.

A clear statement of intent

Puma 700LM II CNC Horizontal Single Turret Lathes

Mills CNC supplied NTG Precision Engineers with a large-capacity DN Solutions multi-tasking turning centre, a 24” chuck Puma 700LM II at the company’s manufacturing facility in Gateshead. The Puma lathe will be used to machine high-precision components for clients in the defence, oil & gas, subsea, automotive, food production & power generation sectors.

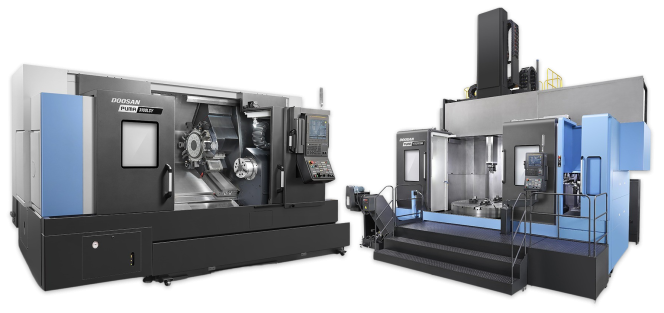

Related Series from CNC Horizontal Single Turret Lathes

Why choose Mills CNC

Why choose Mills CNC

Mills CNC are much more than just a Doosan distributor, our services and support ensure that you can get exactly what you need from financing options to training for your team.

CNC Solutions

Not sure what you need? Mills CNC can help you incorporate your DNM 200 5AX into a turnkey or automated solution that works perfectly for your business.

CNC Automation Systems

From automated Cobots providing machine tending operations, to a bespoke system of sensors, controls and actuators to automate a manufacturing process, Mills CNC can provide an efficient, effective automation solution for you.

Turnkey Solutions

A turnkey solution is more than just a machine, it’s a full service solution that ensures that your CNC setup is perfectly tailored to your manufacturing needs. This can often include automation for a fully streamlined process.

Talk to Mills about this series

Whether you’re ready to order or want some more details about this product, fill out our enquiry form and we’ll get right back to you.

"*" indicates required fields