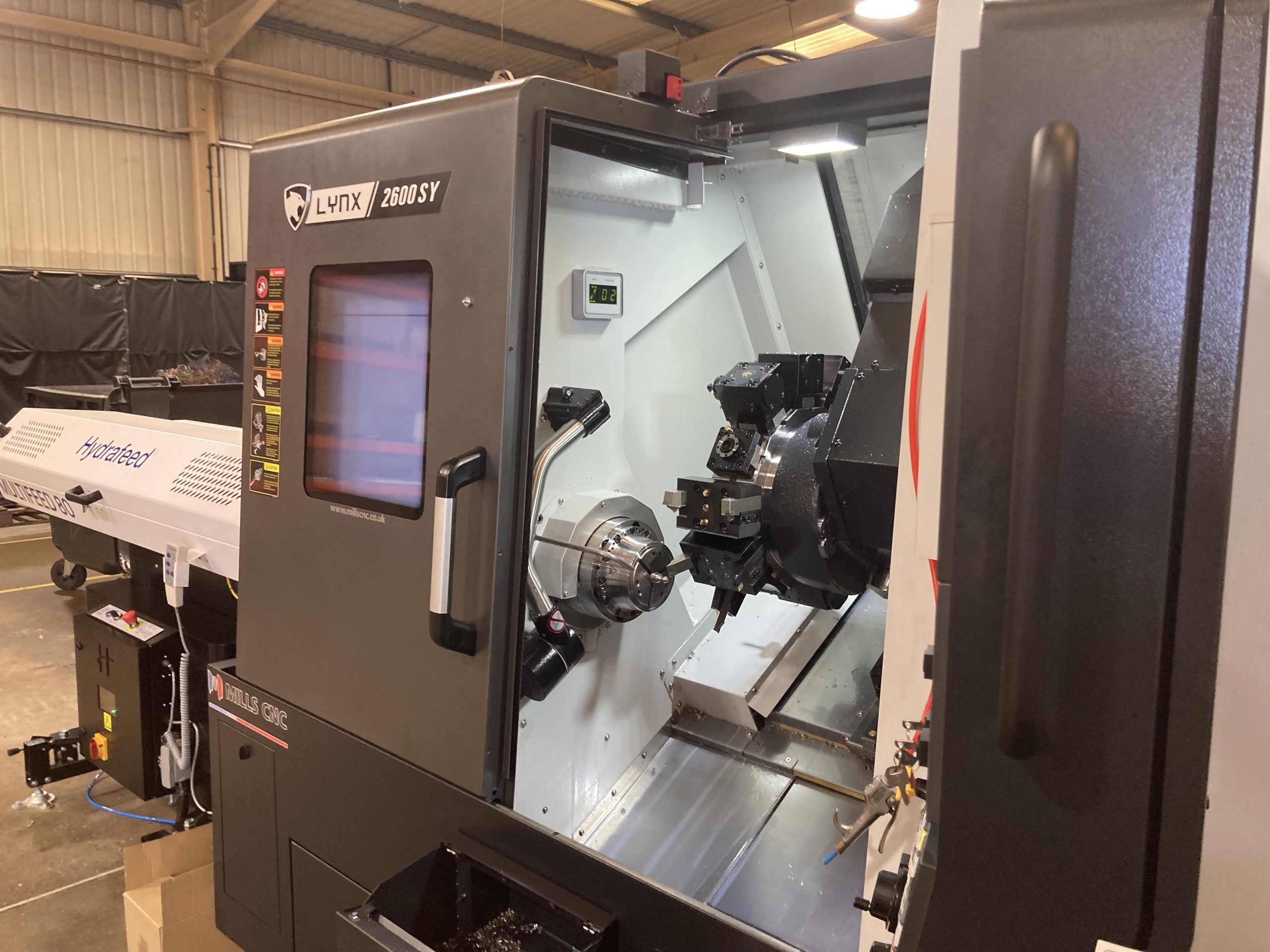

Lynx 2600SY

DN Solutions (formerly Doosan) Lynx 2600SY Horizontal Single Turret Lathe

Lynx 2600SY Description

DN Solutions (formerly Doosan) Lynx 2600SY Horizontal Single Turret Lathe

Product specifications

Lynx 2600SY

CNC Horizontal Single Turret Lathes

- 10” chuck

- 81mm bar diameter

- 18.5kW/3500rpm spindle

Lynx 2600Y

CNC Horizontal Single Turret Lathes

- 10” chuck

- 81mm bar diameter

- 18.5kW/3500rpm spindle

Related Case Studies

Latest investment underlines and signifies future direction of travel

Lynx 2600SY Horizontal Single Turret Lathe

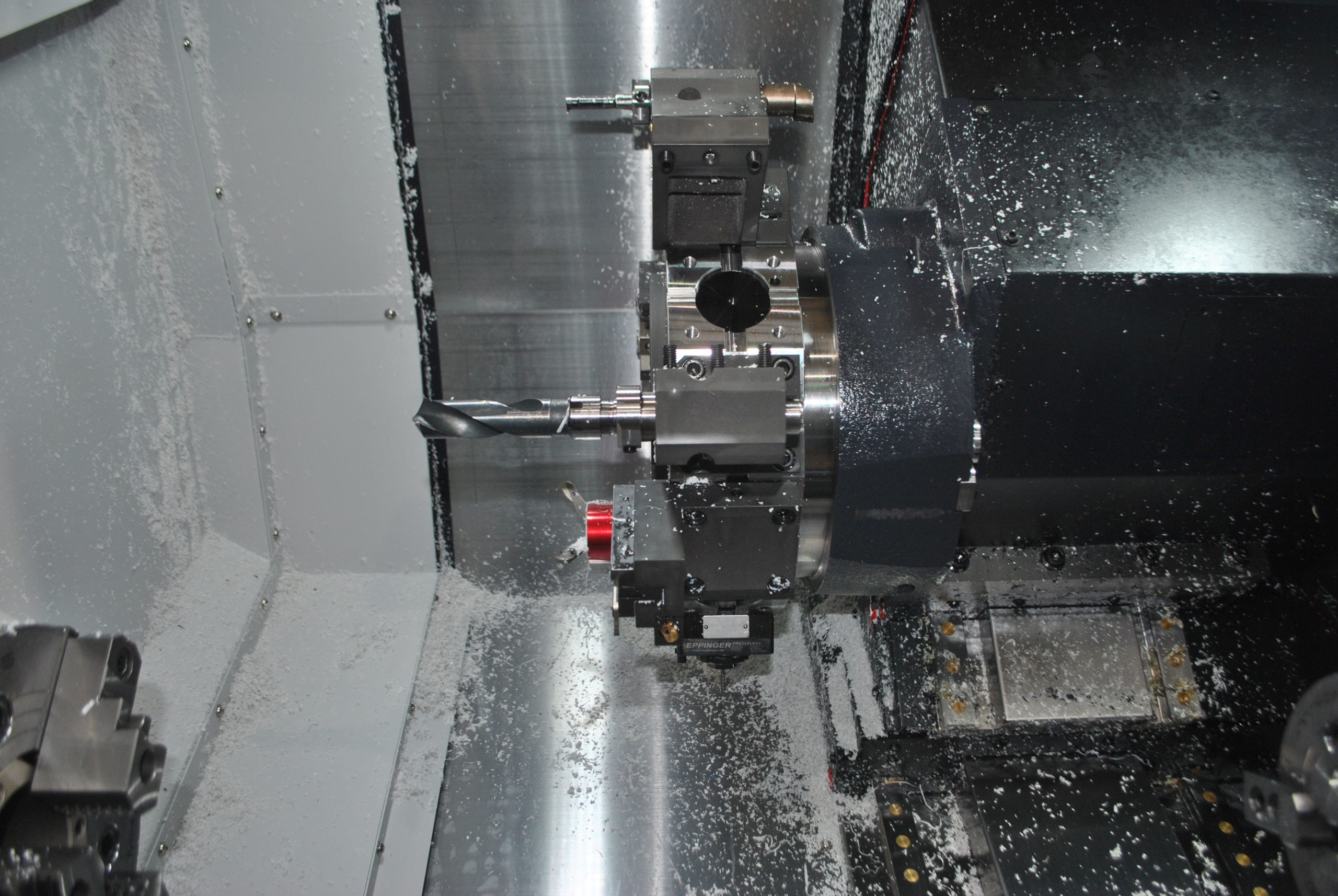

Leading precision conveyor system component manufacturer, Arnott Handling Equipment, invests in a new, multi-tasking lathe and a high-performance bar feeder to automate small part processing operations.

Productivity and efficiency improvements at the double

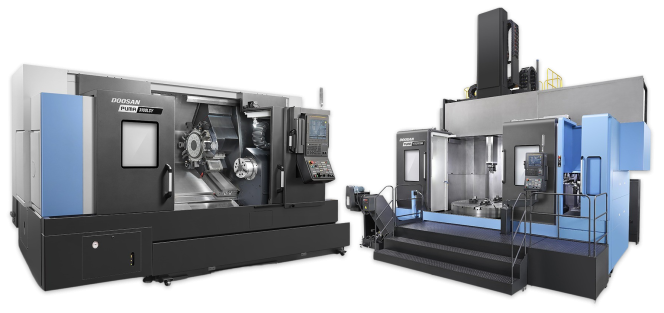

Doosan Puma 2600SY II Horizontal Single Turret Lathes

Northampton based ABG Rubber & Plastics Ltd improved productivity and efficiencies using DN Solutions’ Lynx 2600SY multi-tasking turning centres from Mills CNC. ABG machine components from a engineering plastics such as PEEK, PVDF, Nylon 6 & Polyethylene for customers in automotive, medical, pharmaceutical, construction and food & beverage industries.

A clear statement of intent

Doosan Puma 2600SY II Horizontal Single Turret Lathes

A Ripon design, manufacturing & fabrication specialist has created a machine shop from scratch with Doosan machines from Mills CNC. D & M’s new facility was supplied with a Puma 2600SY Mk II lathe, a Lynx 2100A lathe & two DNM 6700 vertical machining centres which have helped establish a revenue stream supplying high-precision, complex parts to new customers.

Why choose Mills CNC

Why choose Mills CNC

Mills CNC are much more than just a Doosan distributor, our services and support ensure that you can get exactly what you need from financing options to training for your team.

CNC Solutions

Not sure what you need? Mills CNC can help you incorporate your DNM 200 5AX into a turnkey or automated solution that works perfectly for your business.

CNC Automation Systems

From automated Cobots providing machine tending operations, to a bespoke system of sensors, controls and actuators to automate a manufacturing process, Mills CNC can provide an efficient, effective automation solution for you.

Turnkey Solutions

A turnkey solution is more than just a machine, it’s a full service solution that ensures that your CNC setup is perfectly tailored to your manufacturing needs. This can often include automation for a fully streamlined process.

Talk to Mills about this series

Whether you’re ready to order or want some more details about this product, fill out our enquiry form and we’ll get right back to you.

"*" indicates required fields