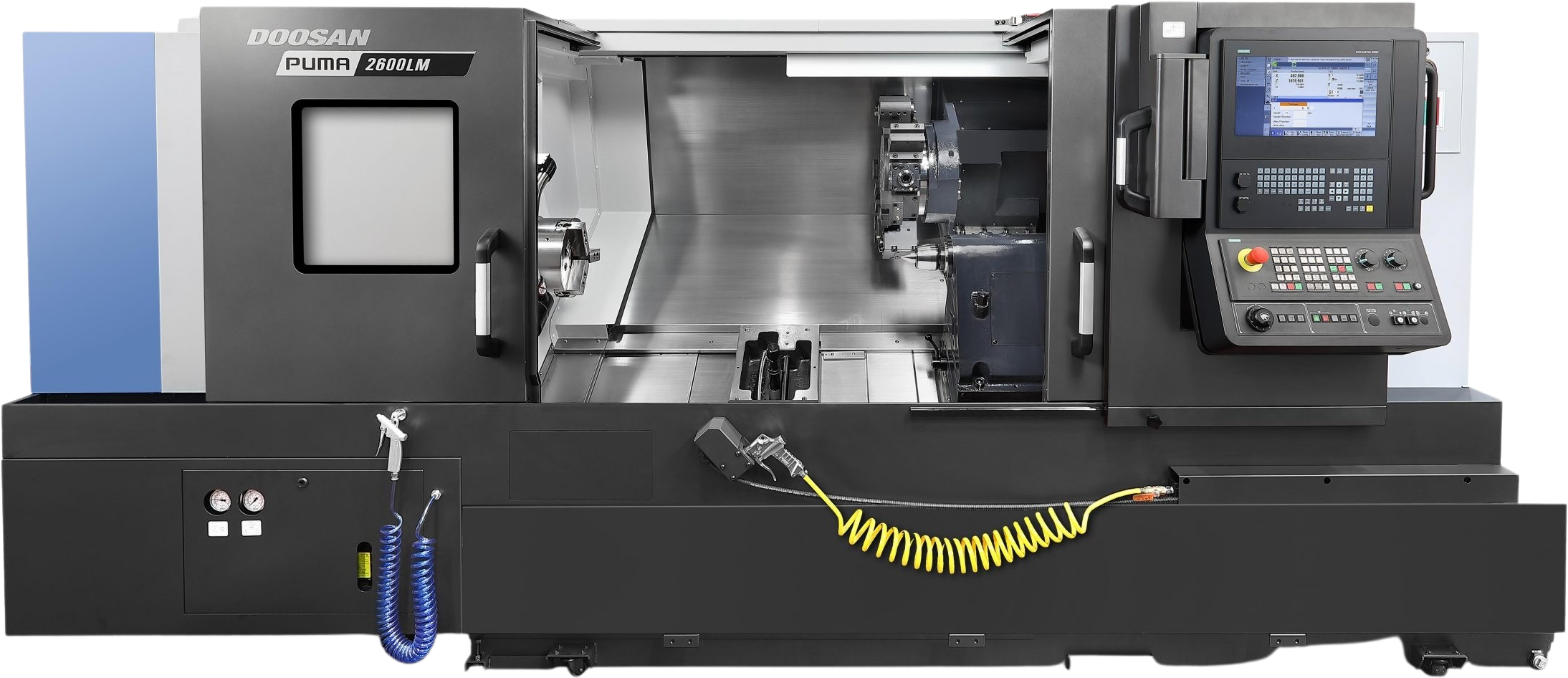

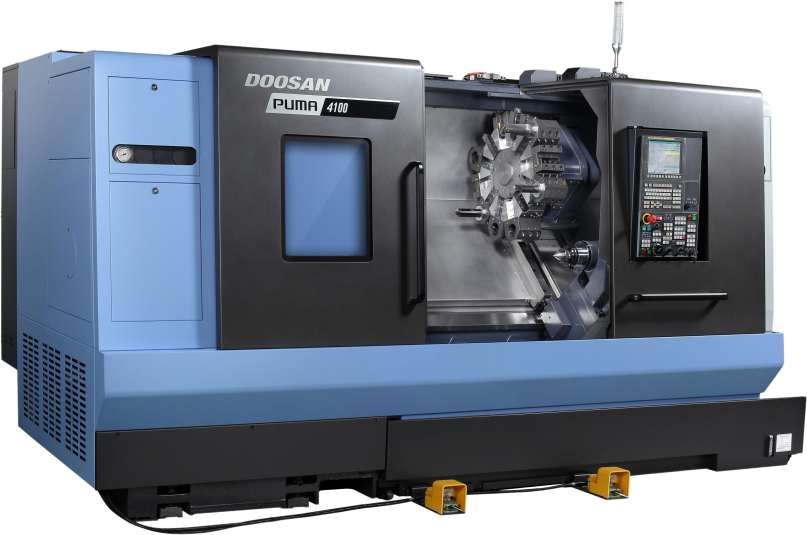

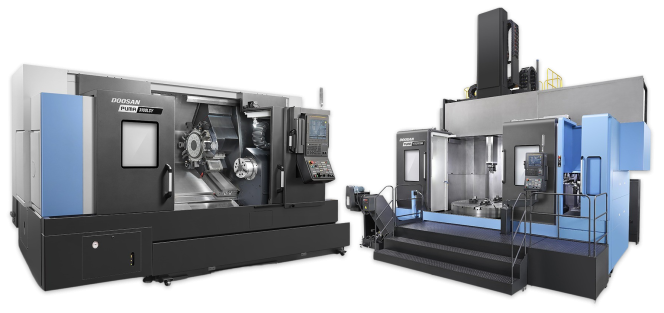

Puma 4100 Series

DN Solutions (formerly Doosan) Puma 4100 lathe series

Puma 4100 Series Description

The new DN Solutions Puma 4100 series replaces the iconic Puma 400 range and is packed with productivity enhancing features for manufacturers looking for the next big thing in turning.

Puma 4100 lathes are powerful, heavy-duty and reliable machines equipped with advanced high-torque spindles, servo-driven turrets and a box guide-way design for extra rigidity and improved cutting performance.

These lathes have large chuck size options (12”, 15”, 21”) and bar diameter capacity that ranges from 102mm through to 165mm. The lathes have been designed to machine large and heavy work-pieces, and deliver outstanding part accuracies, surface finishes and process reliability.

Puma 4100 lathes with long beds and driven tools are available.

Product specifications

Puma 4100XLMC

CNC Horizontal Single Turret Lathes

- 21” chuck

- 165.5mm bar diameter

- 37kW/1500rpm spindle

Puma 4100XLMB

CNC Horizontal Single Turret Lathes

- 15” chuck

- 116.5mm bar diameter

- 30kW/2000rpm spindle

Puma 4100XLMA

CNC Horizontal Single Turret Lathes

- 12” chuck

- 102mm bar diameter

- 30kW/3000rpm spindle

Puma 4100XLC

CNC Horizontal Single Turret Lathes

- 21” chuck

- 165.5mm bar diameter

- 37kW/1500rpm spindle

Puma 4100XLB

CNC Horizontal Single Turret Lathes

- 15” chuck

- 116.5mm bar diameter

- 35kW/2000rpm spindle

Puma 4100XLA

CNC Horizontal Single Turret Lathes

- 12” chuck

- 102mm bar diameter

- 35kW/3000rpm spindle

Puma 4100MC

CNC Horizontal Single Turret Lathes

- 21” chuck

- 165.5mm bar diameter

- 37kW/1500rpm spindle

Puma 4100MB

CNC Horizontal Single Turret Lathes

- 15” chuck

- 116.5mm bar diameter

- 30kW/2000rpm spindle

Puma 4100MA

CNC Horizontal Single Turret Lathes

- 12” chuck

- 102mm bar diameter

- 30kW/3000rpm spindle

Puma 4100LMC

CNC Horizontal Single Turret Lathes

- 21” chuck

- 165.5mm bar diameter

- 37kW/1500rpm spindle

Puma 4100LMB

CNC Horizontal Single Turret Lathes

- 15” chuck

- 116.5mm bar diameter

- 30kW/2000rpm spindle

Puma 4100LMA

CNC Horizontal Single Turret Lathes

- 12” chuck

- 102mm bar diameter

- 30kW/3000rpm spindle

Related Case Studies

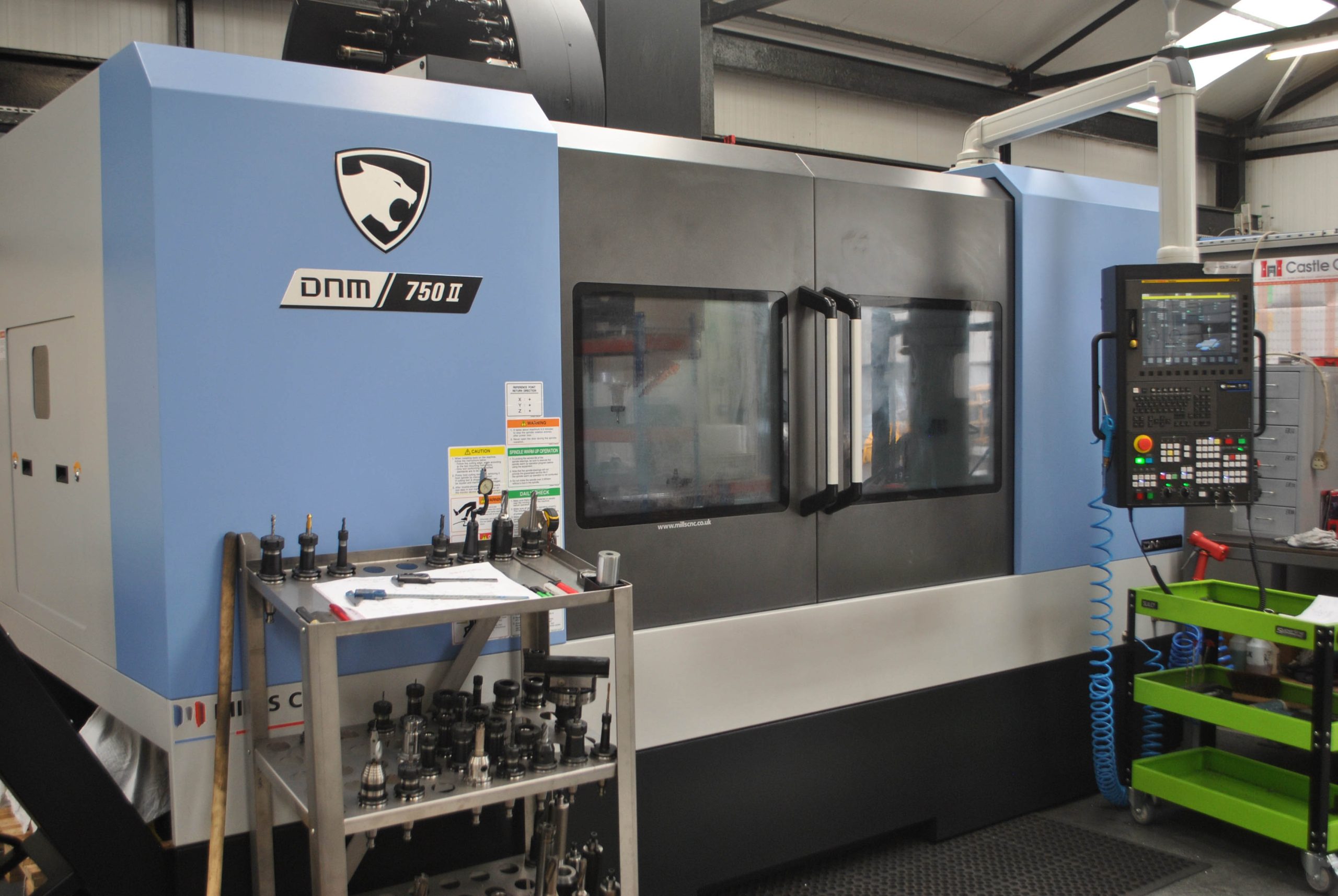

Great machines. Great service. Great decision.

Puma 4100LB Horizontal Single Turret Lathe

Wordsley General Engineering’s decision to invest in a DNM 750 II vertical machining centre and Puma 4100LB horizontal lathe from Mills CNC is paying dividends resulting in the company having a full order book.

Fit for the future.

Puma 4100MB Horizontal Single Turret Lathe

Somerset based Watson Gym Equipment, manufacturer of personal training gym equipment invested in two Doosan turning centres and a Cobot. The 4100MB horizontal single turret lathe has been used to machine their Pro Olympic weight plates & dumbbell handles from marine grade stainless steel, and aided by the Cobot has helped production capabilities increase significantly.

Related Series from CNC Horizontal Single Turret Lathes

Why choose Mills CNC

Why choose Mills CNC

Mills CNC are much more than just a Doosan distributor, our services and support ensure that you can get exactly what you need from financing options to training for your team.

CNC Solutions

Not sure what you need? Mills CNC can help you incorporate your DNM 200 5AX into a turnkey or automated solution that works perfectly for your business.

CNC Automation Systems

From automated Cobots providing machine tending operations, to a bespoke system of sensors, controls and actuators to automate a manufacturing process, Mills CNC can provide an efficient, effective automation solution for you.

Turnkey Solutions

A turnkey solution is more than just a machine, it’s a full service solution that ensures that your CNC setup is perfectly tailored to your manufacturing needs. This can often include automation for a fully streamlined process.

Talk to Mills about this series

Whether you’re ready to order or want some more details about this product, fill out our enquiry form and we’ll get right back to you.

"*" indicates required fields