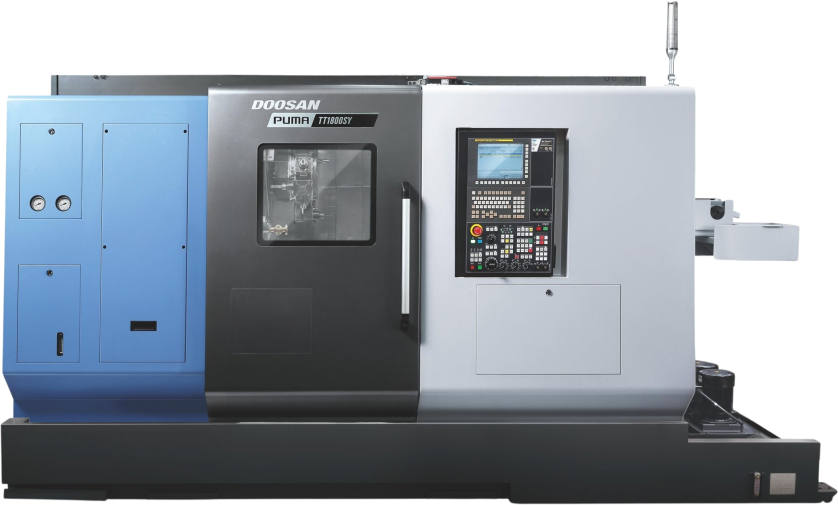

Puma TT Series

DN Solutions (formerly Doosan) Twin-spindle/Twin-turret machines

Puma TT Series Description

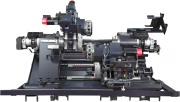

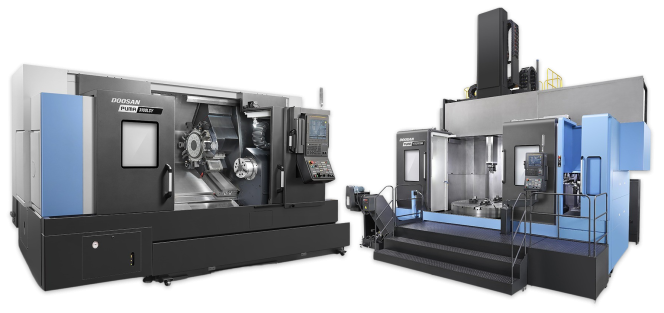

The DN Solutions range of Twin-Turret/Twin-Spindle multi-axis turning centres combine Y-axis functionality, twin spindles and an upper and lower turret to maximise productivity. There are two models in the range – the TT 1800SY and the larger TT 2500SY.

The TT 1800SY has an 8″chuck/65mm bar capacity, with both spindles providing 22kW 5,000rpm power and performance, and both turrets offering 12/24 positions. The machine has Driven Tools (5.5kW 5,000rpm) and ±50mm Y-axis capability.

The larger TT 2500SY is similarly impressive and is equipped with a 10″ chuck /76mm bar capacity, with both spindles providing 26kW 3,500rpm power and performance, and both turrets offering 12 positions. The machine has Driven Tools (5.5kW 4,000rpm) and ±60mm Y-axis capability.

Product specifications

Puma TT2500SY

Twin Turret Horizontal CNC Lathes

- 10” chuck

- 26kW/3500rpm spindle

- 390 mm max turning diameter

Puma TT2500MS

Twin Turret Horizontal CNC Lathes

- 10” chuck

- 26kW/3500rpm spindle

- 350 mm max turning diameter

Puma TT2100SYYB

Twin Turret Horizontal CNC Lathes

- 10” chuck

- 81mm bar diameter

- 22kW/3500rpm spindle

Puma TT2100SYY

Twin Turret Horizontal CNC Lathes

- 8” chuck

- 65mm bar diameter

- 25kW/5000rpm spindle

Puma TT1800SY

Twin Turret Horizontal CNC Lathes

- 8” chuck

- 65mm bar diameter

- 22kW/5000rpm spindle

Puma TT1800MS

Twin Turret Horizontal CNC Lathes

- 8” chuck

- 65mm bar diameter

- 22kW/5000rpm spindle

Puma TT1300SYYB

Twin Turret Horizontal CNC Lathes

- 6” chuck

- 51mm bar diameter

- 15kW/6000rpm spindle

Puma TT1300SYY

Twin Turret Horizontal CNC Lathes

- 5” chuck

- 42mm bar diameter

- 11kW/6000rpm spindle

Puma TT1300SYB

Twin Turret Horizontal CNC Lathes

- 6” chuck

- 51mm bar diameter

- 15kW/6000rpm spindle

Puma TT1300SY

Twin Turret Horizontal CNC Lathes

- 5” chuck

- 42mm bar diameter

- 11kW/6000rpm spindle

Related Case Studies

Loads better

Automated Manufacturing Cell for Puma TT2500SY Twin Turret Horizontal Lathe

A new SYNERGi automation system from Mills CNC has helped Bindon Engineering improve an existing in-house machining process by eliminating frequent, disruptive and costly manual part loading and unloading operations.

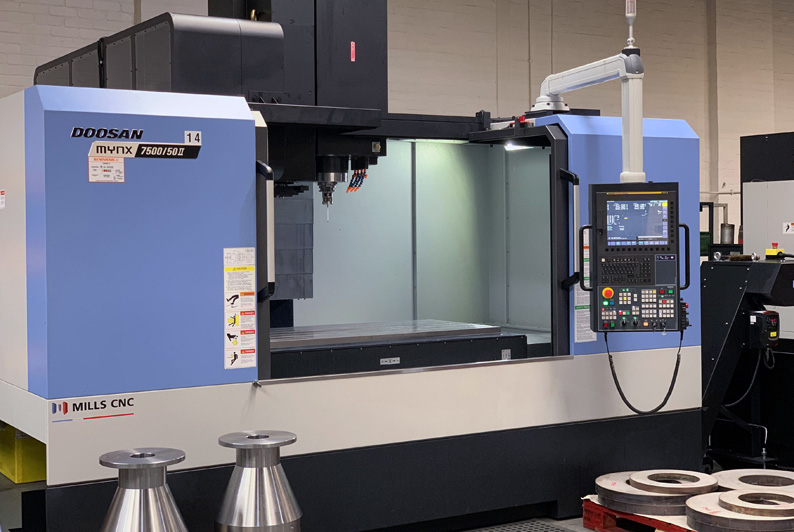

Agility and adaptability: the keys to business growth, success and longevity

TT1800SY Twin Turret Horizontal CNC Lathe

Precision subcontract specialists Standish Engineering Co invest in a DN Solutions twin-pallet vertical machining centre and a DN Solutions twin-turret, twin-spindle turning centre, helping the company respond to customers’ changing needs and requirements with speed and efficiency.

Well prepared – for all eventualities.

Puma TT2100SYY Twin Turret Horizontal CNC Lathe

Tyne & Wear based Washington Components, a subcontract specialist serving the oil & gas subsea sector, has invested in new Doosan machine tools. The 1st acquisition, a Puma TT 2100 SYY twin-turret, twin-spindle turning centre demonstrates the depth and sophistication of machining operations required of subcontractors operating in the subsea, off-shore & wind energy markets.

Related Series from Twin Turret Horizontal CNC Lathes

Why choose Mills CNC

Why choose Mills CNC

Mills CNC are much more than just a Doosan distributor, our services and support ensure that you can get exactly what you need from financing options to training for your team.

CNC Solutions

Not sure what you need? Mills CNC can help you incorporate your DNM 200 5AX into a turnkey or automated solution that works perfectly for your business.

CNC Automation Systems

From automated Cobots providing machine tending operations, to a bespoke system of sensors, controls and actuators to automate a manufacturing process, Mills CNC can provide an efficient, effective automation solution for you.

Turnkey Solutions

A turnkey solution is more than just a machine, it’s a full service solution that ensures that your CNC setup is perfectly tailored to your manufacturing needs. This can often include automation for a fully streamlined process.

Talk to Mills about this series

Whether you’re ready to order or want some more details about this product, fill out our enquiry form and we’ll get right back to you.

"*" indicates required fields