DEM Series

DN Solutions (formerly Doosan) DEM vertical machining centres

DEM Series Description

The DEM series includes the DN Solutions DEM 4000, a compact, high-performance vertical machining centre.

Despite its relatively small footprint, the machine punches well above its weight and is packed with a range of productivity-enhancing features.

Product specifications

DEM 4000

View

Related Case Studies

Doosan machines integral to Centre’s success.

Doosan DEM 4000 Vertical Machining Centre

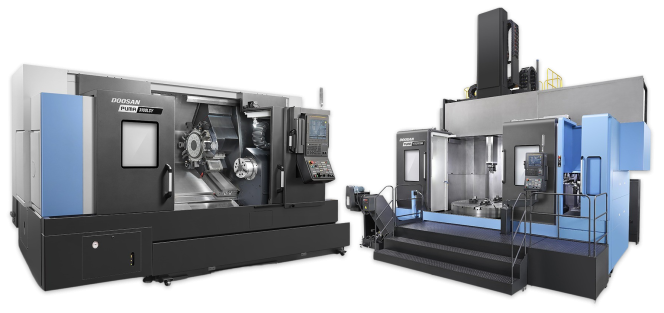

Mills CNC supplied two Doosan machines, a Lynx 2100LMB multi-tasking lathe and a flexible DEM 4000 vertical machining centre to the Advancing Manufacturing Centre at West Highland College in Fort William. The centre is a research, design and manufacturing hub that was setup to increase the manufacturing competitiveness of SMEs in Scotland.

Related Series from Vertical Machining Centres

Why choose Mills CNC

Why choose Mills CNC

Mills CNC are much more than just a Doosan distributor, our services and support ensure that you can get exactly what you need from financing options to training for your team.

CNC Solutions

Not sure what you need? Mills CNC can help you incorporate your DNM 200 5AX into a turnkey or automated solution that works perfectly for your business.

CNC Automation Systems

From automated Cobots providing machine tending operations, to a bespoke system of sensors, controls and actuators to automate a manufacturing process, Mills CNC can provide an efficient, effective automation solution for you.

Turnkey Solutions

A turnkey solution is more than just a machine, it’s a full service solution that ensures that your CNC setup is perfectly tailored to your manufacturing needs. This can often include automation for a fully streamlined process.

Talk to Mills about this series

Whether you’re ready to order or want some more details about this product, fill out our enquiry form and we’ll get right back to you.

"*" indicates required fields