Leaders In Die and Mould Machine Tools

The use of CNC machining to cut dies and moulds ensures high tolerance, precision, repeatability, and consistency in production.

The DN Solutions Die and Mould Machine Tools are optimised for high speed, high precision machining and have built up enviable levels of trust amongst tool makers around the globe.

The Die and Mould Machining Tools encompass everything from compression moulds to press tooling and fixturing and provide an accurate, highly efficient and labour-saving method of creating moulds for tool creation.

Our Products

Select the machine type or series you’d like to explore, or scroll down for a full list of products in this category, and filter by the factors that matter to you.

All Die and Mould Machine Tools

Showing 1-12 of 15 products

VX 6500G

Die and Mould Machine Tools

- 18.5kW/12000rpm spindle

- 30ea tool stations

- 4390 x 2940 x 3100 mm (LxWxH)

VX 6500C

Die and Mould Machine Tools

- 18.5kW/12000rpm spindle

- 30ea tool stations

- 3000 x 2920 x 3100 mm (LxWxH)

MP 6500

Die and Mould Machine Tools

- 22kW/40000rpm spindle

- 30ea tool stations

- 3315 x 2820 x 3036 mm (LxWxH)

NX 5500 II

Die and Mould Machine Tools

- 22kW/40000rpm spindle

- 30ea tool stations

- 2530 x 2900 x 3064 mm (LxWxH)

DVM 650 II

Die and Mould Machine Tools

- 22kW/20000rpm spindle

- 30ea tool stations

- 2692 x 3350 x 2905 mm (LxWxH)

DVM 500 II

Die and Mould Machine Tools

- 22kW/20000rpm spindle

- 30ea tool stations

- 2462 x 3350 x 2789 mm (LxWxH)

VM 6500

Die and Mould Machine Tools

- 15.6kW/12000rpm spindle

- 40ea tool stations

- 2674 x 3350 x 2950 mm (LxWxH)

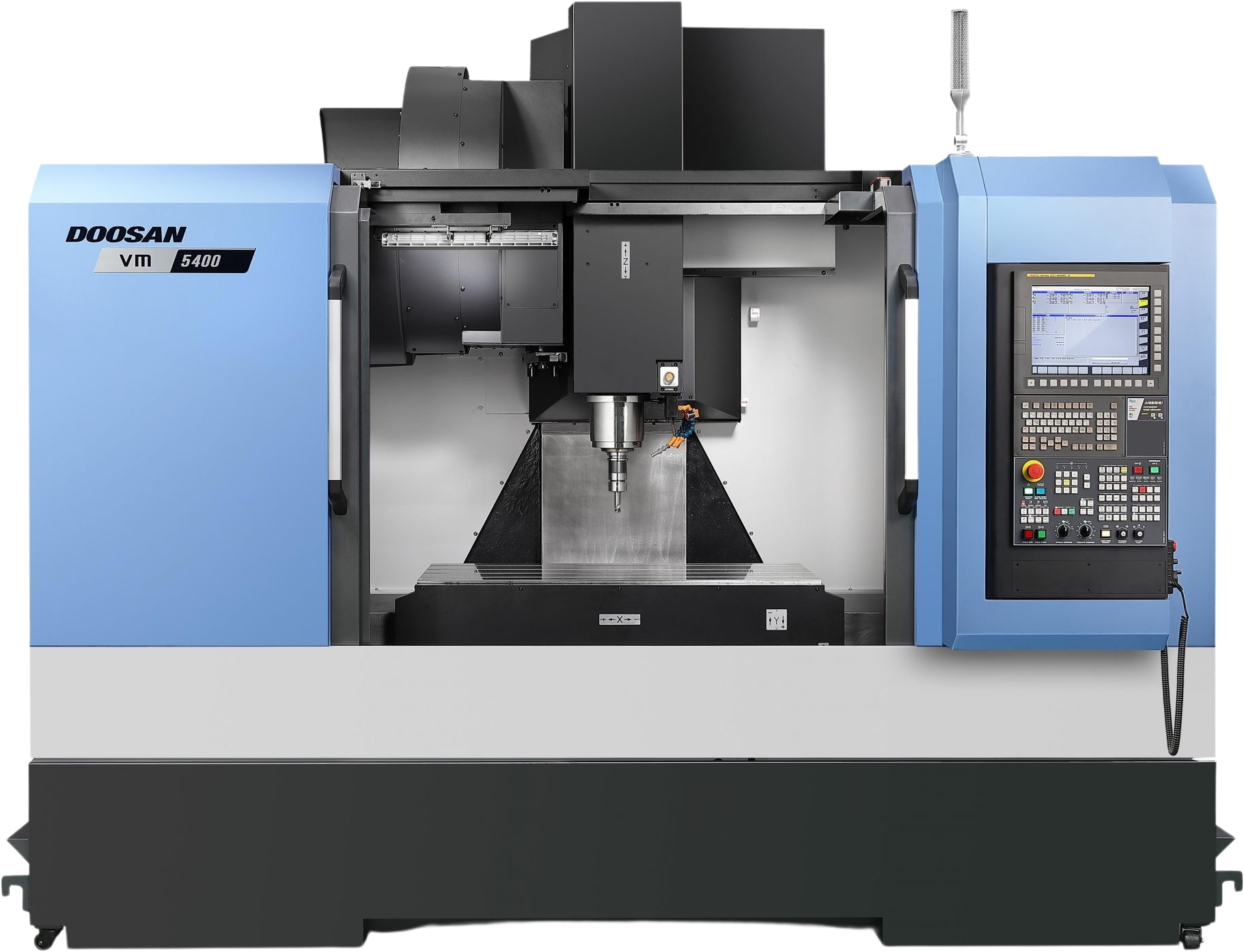

VM 5400

Die and Mould Machine Tools

- 15.6kW/12000rpm spindle

- 40ea tool stations

- 2444 x 3350 x 2855 mm (LxWxH)

VM 1260

Die and Mould Machine Tools

- 30kW/12000rpm spindle

- 40ea tool stations

- 5645 x 6938 x 3930 mm (LxWxH)

VM 960L

Die and Mould Machine Tools

- 30kW/12000rpm spindle

- 40ea tool stations

- 5392 x 6800 x 3545 mm (LxWxH)

VM 960

Die and Mould Machine Tools

- 30kW/12000rpm spindle

- 40ea tool stations

- 5392 x 6400 x 3545 mm (LxWxH)

VM 750L

Die and Mould Machine Tools

- 30kW/12000rpm spindle

- 40ea tool stations

- 5180 x 5500 x 3545 mm (LxWxH)

- 1

- 2

Showing 1-12 of 16 products

Filter

Get in touch

If you’d like to find out more about any of our machines, if you’d like a brochure or want to book a demo, then we’d love to hear from you. Whether you’re looking for a specific machine, or want to know more about our turnkey or automated solutions, Mills CNC can help.