Horizontal Single Turret Lathes

Why Choose A Horizontal Lathe Machine?

There are many benefits of choosing a CNC horizontal single turret lathe. Generally they are easy to use and maintain, highly accurate, increase productivity, flexible and reliable.

Since our range of CNC Lathe Machine is so extensive, you can find the perfect tool for your projects. With many Doosan machines boasting large turning diameters and turning lengths as well as high power spindles.

Mills CNC has one of the most comprehensive ranges of turret lathes and turning centres in the market. Our portfolio of machines features chuck sizes from 6” to 32” – including machines equipped with sub-spindles, C-axes, Y-axes and driven tools, as well as ultra long-bed models.

Our Products

Select the machine type or series you’d like to explore, or scroll down for a full list of products in this category, and filter by the factors that matter to you.

All CNC Horizontal Single Turret Lathes

Showing 1-12 of 150 products

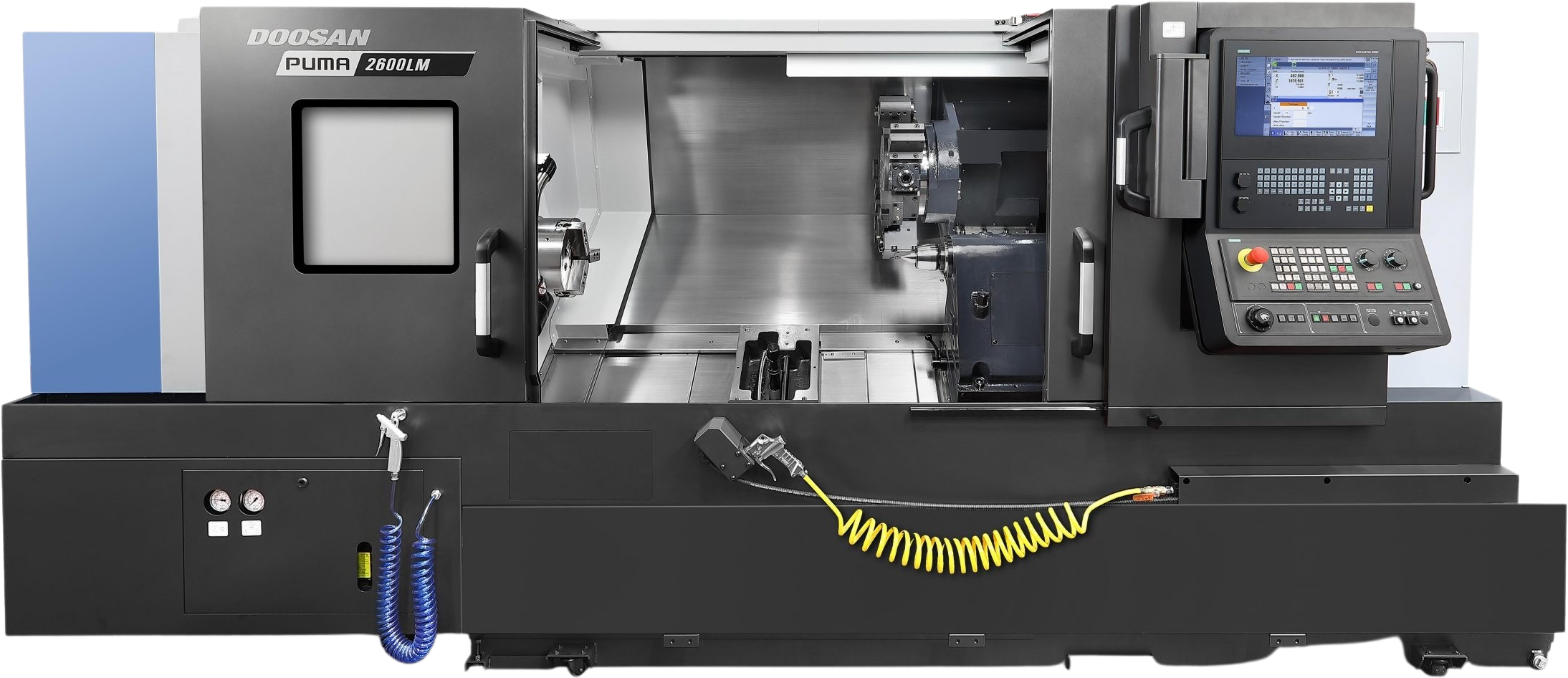

Puma DNT2600LM

CNC Horizontal Single Turret Lathes

- 10” chuck

- 81mm bar diameter

- 22kW/3500rpm spindle

Puma DNT2600L

CNC Horizontal Single Turret Lathes

- 10” chuck

- 81mm bar diameter

- 22kW/3500rpm spindle

Puma DNT2100

CNC Horizontal Single Turret Lathes

- 8” chuck

- 65mm bar diameter

- 18.5kW/4500rpm spindle

Puma DNT2100B

CNC Horizontal Single Turret Lathes

- 10” chuck

- 81mm bar diameter

- 18.5kW/3500rpm spindle

Puma DNT2100MB

CNC Horizontal Single Turret Lathes

- 10” chuck

- 81mm bar diameter

- 18.5kW/3500rpm spindle

Puma DNT2100M

CNC Horizontal Single Turret Lathes

- 8” chuck

- 65mm bar diameter

- 18.5kW/4500rpm spindle

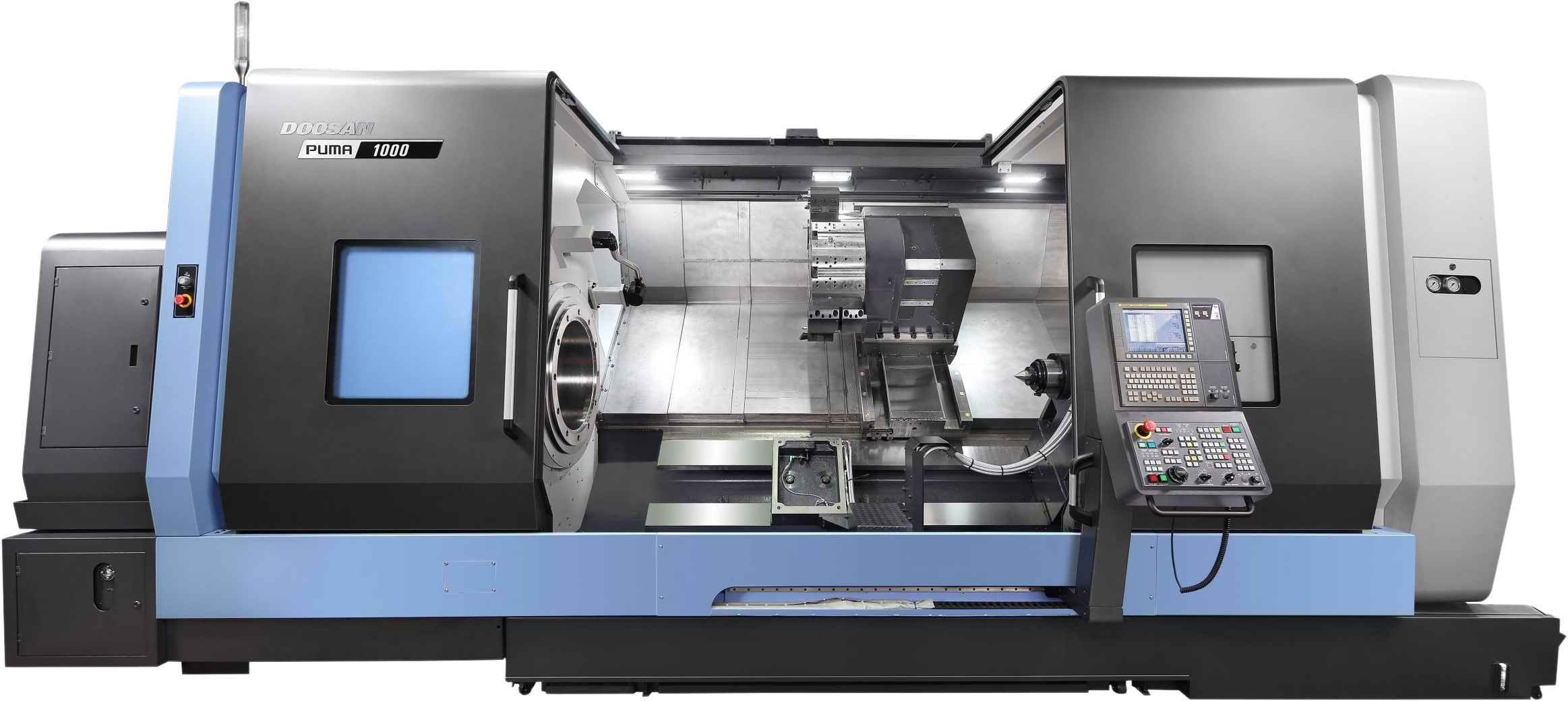

Puma 1000MB

CNC Horizontal Single Turret Lathes

- 32” chuck

- 75kW/300rpm spindle

- 1000 mm max turning diameter

Puma 1000MA

CNC Horizontal Single Turret Lathes

- 32” chuck

- 75kW/500rpm spindle

- 1000 mm max turning diameter

Puma 1000B

CNC Horizontal Single Turret Lathes

- 32” chuck

- 75kW/300rpm spindle

- 1000 mm max turning diameter

Puma 1000A

CNC Horizontal Single Turret Lathes

- 32” chuck

- 75kW/500rpm spindle

- 1000 mm max turning diameter

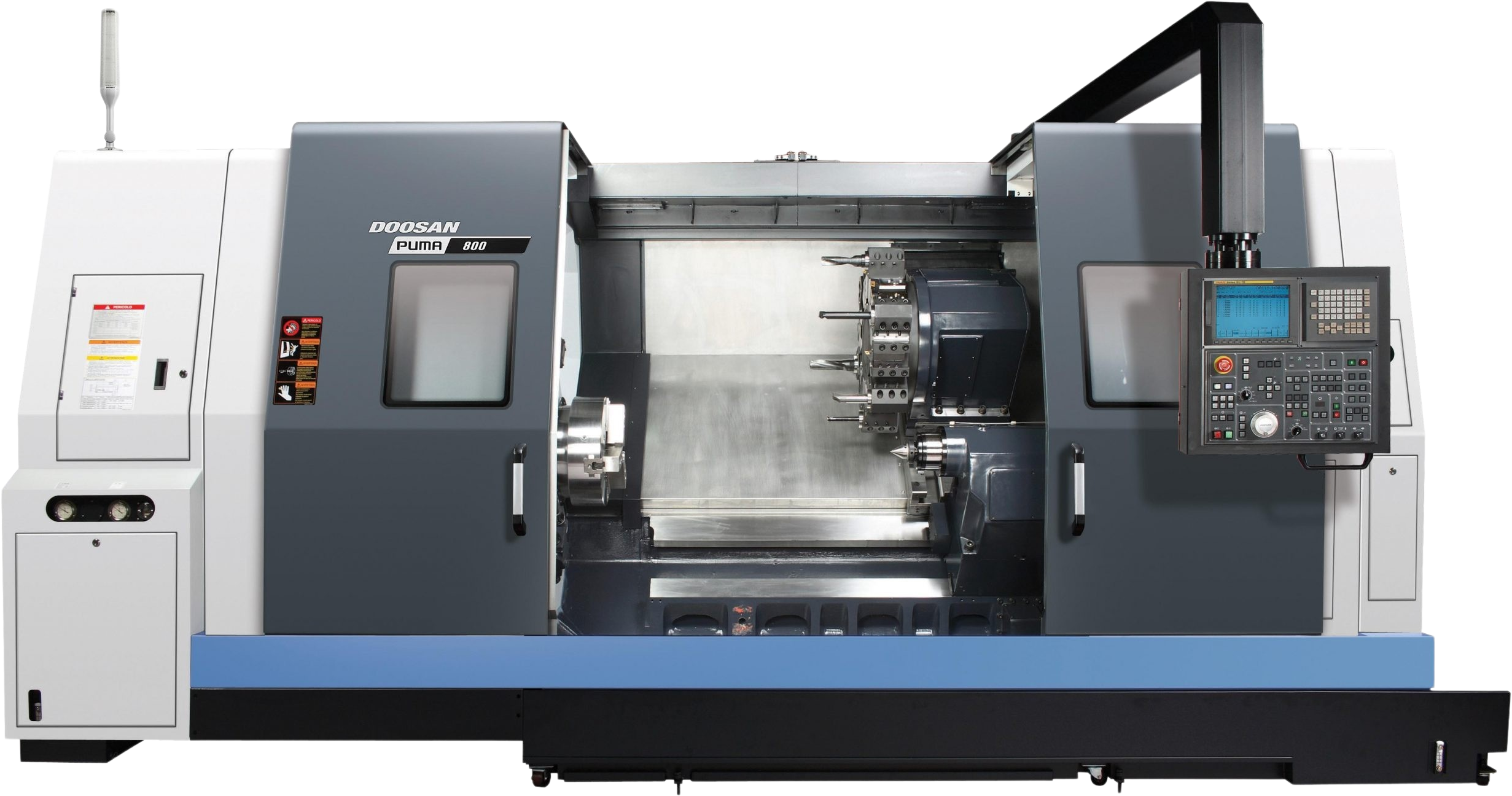

Puma 800XLY II

CNC Horizontal Single Turret Lathes

- 32” chuck

- 55kW/750rpm spindle

- 750 mm max turning diameter

Puma 800XLM II

CNC Horizontal Single Turret Lathes

- 32” chuck

- 55kW/750rpm spindle

- 900 mm max turning diameter

Filter

Related Case Studies

Legends in the making

Lynx 2100 Horizontal Single Turret Lathes

DN Solutions’ Lynx 2100 lathes are the UK and Ireland’s favourite small compact lathe series for small parts processing, backed up by Mills CNC’s best in class after sales service and support.

Selecting the right gear

Lynx 2100LMB Horizontal Single Turret Lathe

Leading motorcycle transmission and gearbox design and manufacturing specialist, Nova Racing Transmissions, invests in a new high-performance Lynx 2100LMB lathe from Mills CNC.

Turning up the volumes!

Puma GT 3100 Horizontal Single Turret Lathe

Due to significant increases in demand for high-precision machined components from oil and gas customers, CNC Technology invests in increasing its in-house turning capacity with a DN Solutions box guideway lathe from Mills CNC.

Get in touch

If you’d like to find out more about any of our machines, if you’d like a brochure or want to book a demo, then we’d love to hear from you. Whether you’re looking for a specific machine, or want to know more about our turnkey or automated solutions, Mills CNC can help.