CNC Lathes

Why Choose CNC Lathes and Turning Centres?

CNC lathes and turning centres are integral to many component manufacturing processes.

The machines are able to produce high-precision, complex parts with intricate features and are widely used to machine components in the aerospace, oil and gas, power generation, motorsport, automotive & medical industries to high accuracies and exacting surface finish requirements.

The size of the CNC lathe machine (chuck & bar diameter size, bed length and the distance between centres) dictates the size of the component that can be machined.

Integrated technologies and additional axes (driven tooling, sub-spindles, in-process measurement, C-axis & Y-axis) increases the CNC lathe or turning centres’ capabilities, enabling precision parts to be machined to completion in fewer set ups.

Furthermore, the cost per part can also be reduced through automation by integrating bar feeders, cobots and SYNERGi systems, enabling the machines to run unattended all day, overnight and even over weekends too.

Our Products

Select the machine type or series you’d like to explore, or scroll down for a full list of products in this category, and filter by the factors that matter to you.

All CNC Lathe Machines & Turning Centres

Showing 1-12 of 210 products

Puma V9300M

Single Turret Vertical Turret Lathe

- 24” chuck

- 930 mm max turning diameter

- 801 mm max turning length

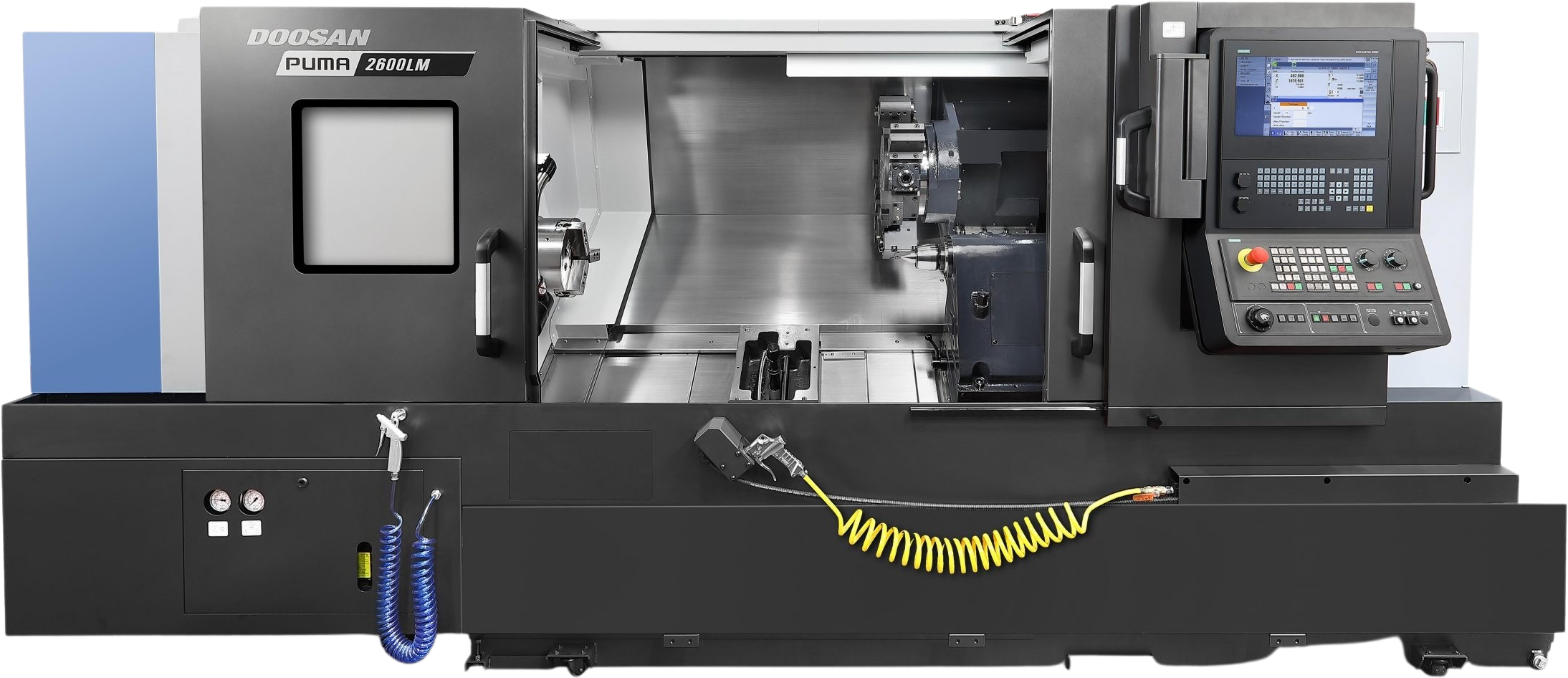

Puma DNT2600LM

CNC Horizontal Single Turret Lathes

- 10” chuck

- 81mm bar diameter

- 22kW/3500rpm spindle

Puma DNT2600L

CNC Horizontal Single Turret Lathes

- 10” chuck

- 81mm bar diameter

- 22kW/3500rpm spindle

Puma DNT2100

CNC Horizontal Single Turret Lathes

- 8” chuck

- 65mm bar diameter

- 18.5kW/4500rpm spindle

Puma DNT2100B

CNC Horizontal Single Turret Lathes

- 10” chuck

- 81mm bar diameter

- 18.5kW/3500rpm spindle

Puma DNT2100MB

CNC Horizontal Single Turret Lathes

- 10” chuck

- 81mm bar diameter

- 18.5kW/3500rpm spindle

Puma DNT2100M

CNC Horizontal Single Turret Lathes

- 8” chuck

- 65mm bar diameter

- 18.5kW/4500rpm spindle

Puma VTR2025M

Ram Type Vertical Borers

- 75kW/200rpm spindle

- 2500 mm max turning diameter

- 1900 mm max turning length

Puma VTR2025

Ram Type Vertical Borers

- 75kW/200rpm spindle

- 2500 mm max turning diameter

- 1900 mm max turning length

Puma VTR1620M

Ram Type Vertical Borers

- 45kW/300rpm spindle

- 2000 mm max turning diameter

- 1800 mm max turning length

Puma VTR1620

Ram Type Vertical Borers

- 45kW/300rpm spindle

- 2000 mm max turning diameter

- 1800 mm max turning length

Puma VTR1216M

Ram Type Vertical Borers

- 45kW/300rpm spindle

- 1600 mm max turning diameter

- 1250 mm max turning length

Filter

Related Case Studies

Legends in the making

Lynx 2100 Horizontal Single Turret Lathes

DN Solutions’ Lynx 2100 lathes are the UK and Ireland’s favourite small compact lathe series for small parts processing, backed up by Mills CNC’s best in class after sales service and support.

Rolling news!

VTR 1216F Ram Type Vertical Borer

Driven forward by the size, power, precision and versatility of their new DN Solutions’ large-capacity, ram-type vertical turning lathe, Bowers & Jones plan for new business opportunities and to consolidate their supply chain position.

Agility and adaptability: the keys to business growth, success and longevity

TT1800SY Twin Turret Horizontal CNC Lathe

Precision subcontract specialists Standish Engineering Co invest in a DN Solutions twin-pallet vertical machining centre and a DN Solutions twin-turret, twin-spindle turning centre, helping the company respond to customers’ changing needs and requirements with speed and efficiency.

Frequently Asked Questions

It can be hard to spot the difference between a CNC lathe and a CNC turning centre at first glance as they perform the same type of task. Both machines can spin material whilst cutting it to create the desired shape – and both offer an automated solution. However, the CNC turning centre goes one step further than a CNC lathe because it can offer automated tool changing, live rotating tools and more.

Put simply, the CNC turning centre is an upgrade of the CNC lathe.

The ideal tool for you depends on the type of production you run. A CNC lathe is suited to short production runs for simple parts such as pins and bushings. This machine is a great choice if you’re looking to carry out quick repairs as it’s easy to set up and run from a CNC program or manually.

A CNC turning centre is preferred for production and material removal. A CNC turning centre is slightly harder to set up compared to the CNC lathe and you can only operate it via a controller. Yet this choice can perform many more automated tasks at a higher rate than a CNC lathe.

CNC lathes are typically used to manufacture parts for the automotive, aerospace and engineering industries. Some wider applications include the electronics, defence and healthcare sectors.

We at Mills CNC hold a large amount of stock of new Doosan lathes and turning centres at our Technology Campus facility in Leamington. To see these machines or any other CNC machines in action, call us on 01926 736736 to book an appointment.

Get in touch

If you’d like to find out more about any of our machines, if you’d like a brochure or want to book a demo, then we’d love to hear from you. Whether you’re looking for a specific machine, or want to know more about our turnkey or automated solutions, Mills CNC can help.