Wide Range of Machine Centres

Class Leading CNC Machining Centre

With significant R&D capabilities, DN Solutions is a global leader in the development and manufacture of high-tech CNC machine centres that efficiently serve the needs of production driven industry sectors, including automotive, aerospace and medical.

The extensive DN Solutions machine tool range is second to none and consistently enjoys the highest levels of customer satisfaction. As well as encompassing best-in-class 5-axis CNC machines, the range includes:

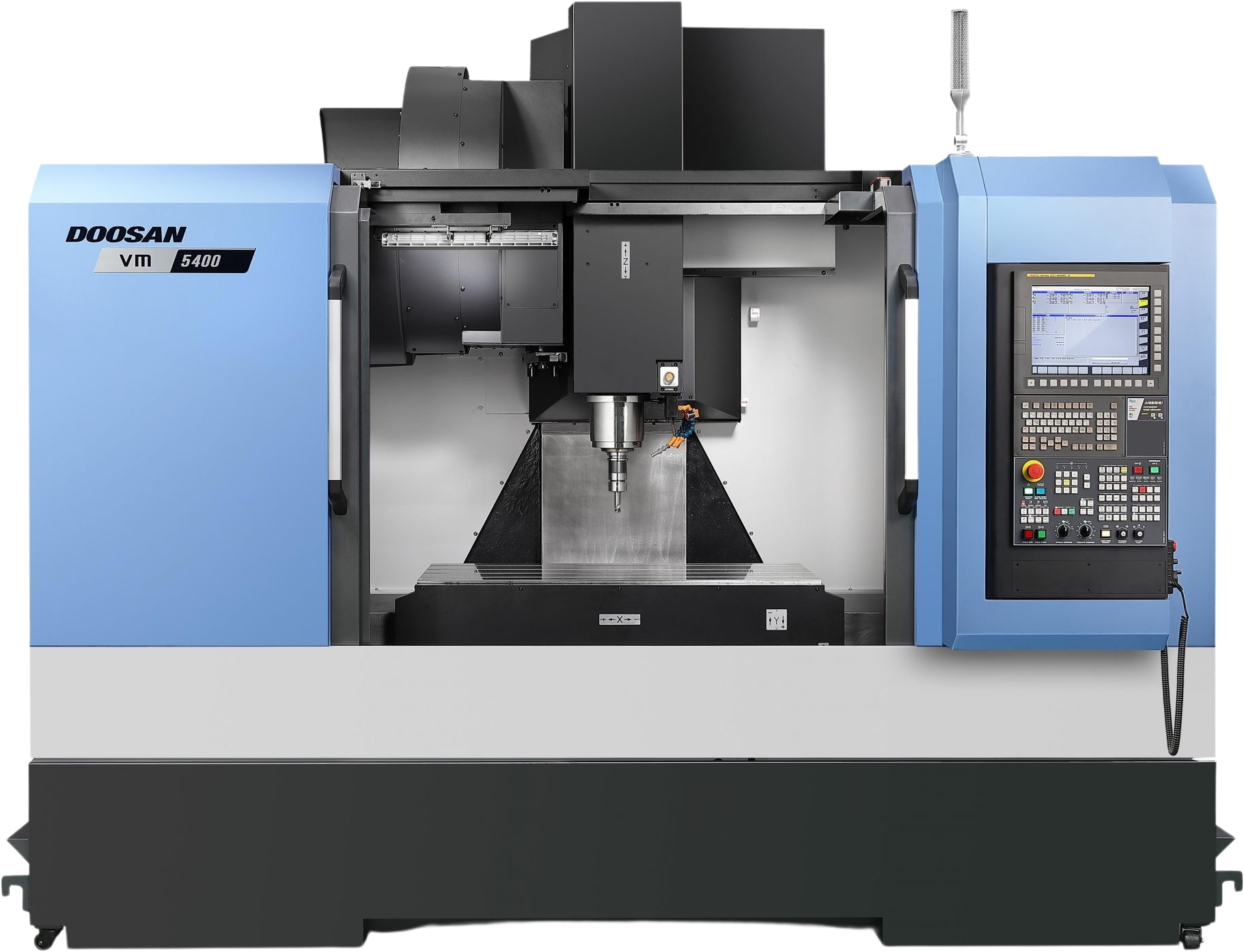

- Vertical Machining Centres

- Twin-Pallet Vertical machining centres

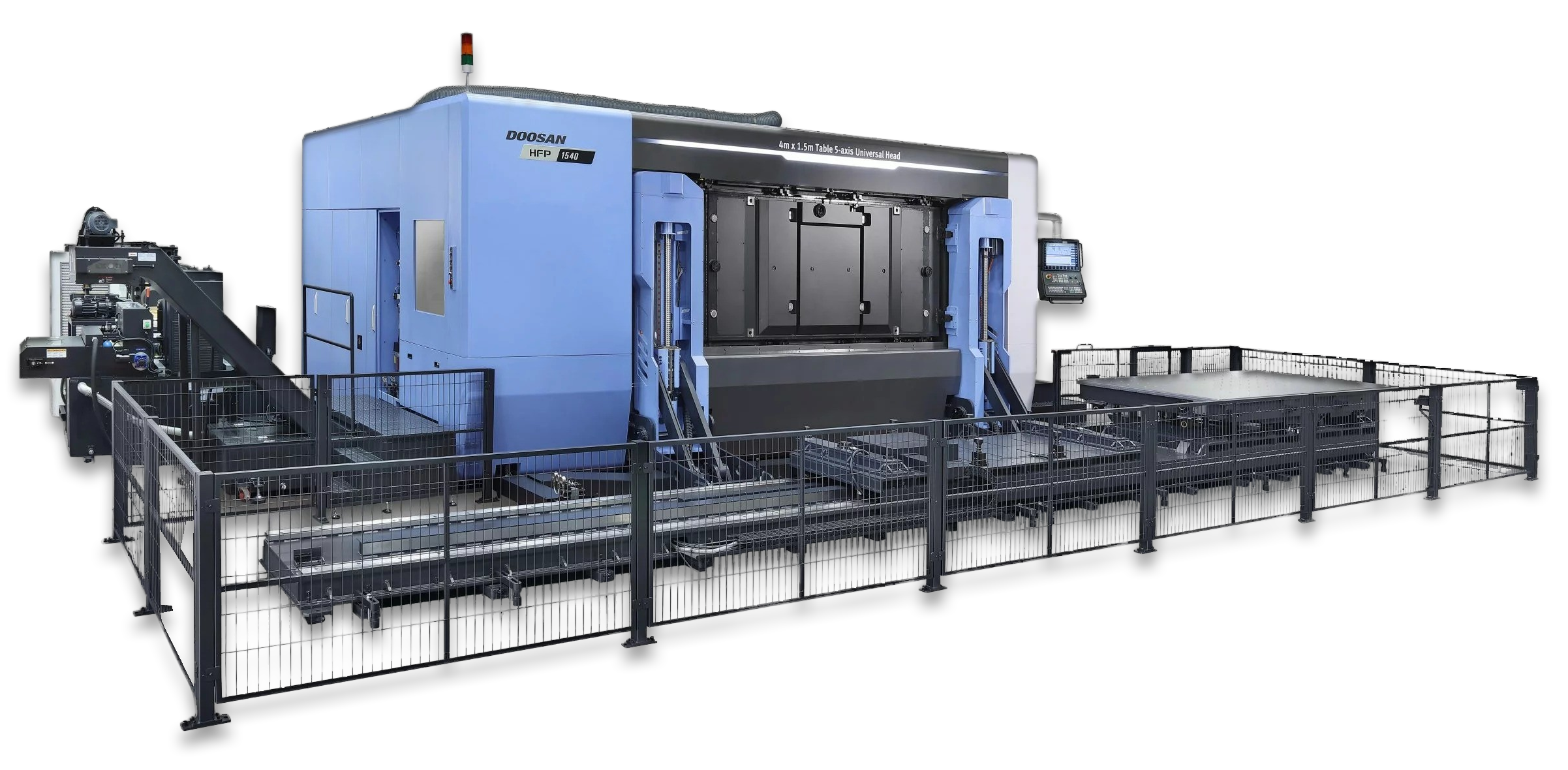

- 5-Axis Vertical machining centres (Best-in-class)

- Horizontal Machining Centres

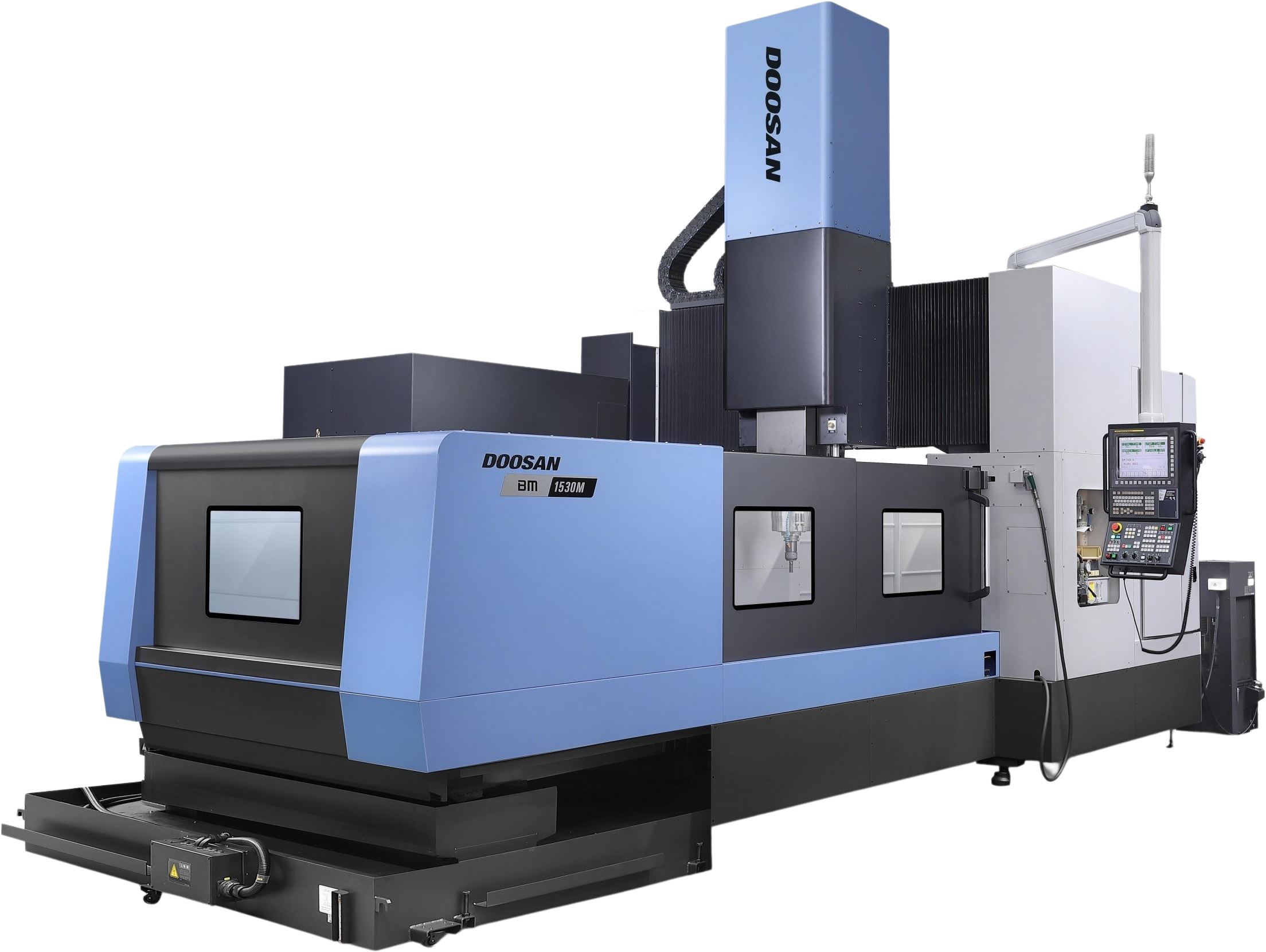

- Double Column Machines

Our Products

Select the machine type or series you’d like to explore, or scroll down for a full list of products in this category, and filter by the factors that matter to you.

All CNC Machining Centres

Showing 49-60 of 93 products

DEM 4000

Vertical Machining Centres

- 7.5kW/8000rpm spindle

- 20ea tool stations

- 1875 x 2200 x 2317 mm (LxWxH)

T 4000HS

Tapping Machining Centres

- 11kW/24000rpm spindle

- 24ea tool stations

- 2560 x 1600 x 2385 mm (LxWxH)

T 4000HP

Tapping Machining Centres

- 6.6kW/12000rpm spindle

- 24ea tool stations

- 2463 x 1620 x 2670 mm (LxWxH)

T 4000L

Tapping Machining Centres

- 13kW/12000rpm spindle

- 24ea tool stations

- 2682 x 2050 x 2380 mm (LxWxH)

T 4000

Tapping Machining Centres

- 13kW/12000rpm spindle

- 24ea tool stations

- 2682 x 1620 x 2380 mm (LxWxH)

T 3600D

Tapping Machining Centres

- 13kW/12000rpm spindle

- 24ea tool stations

- 3684 x 1729 x 2507 mm (LxWxH)

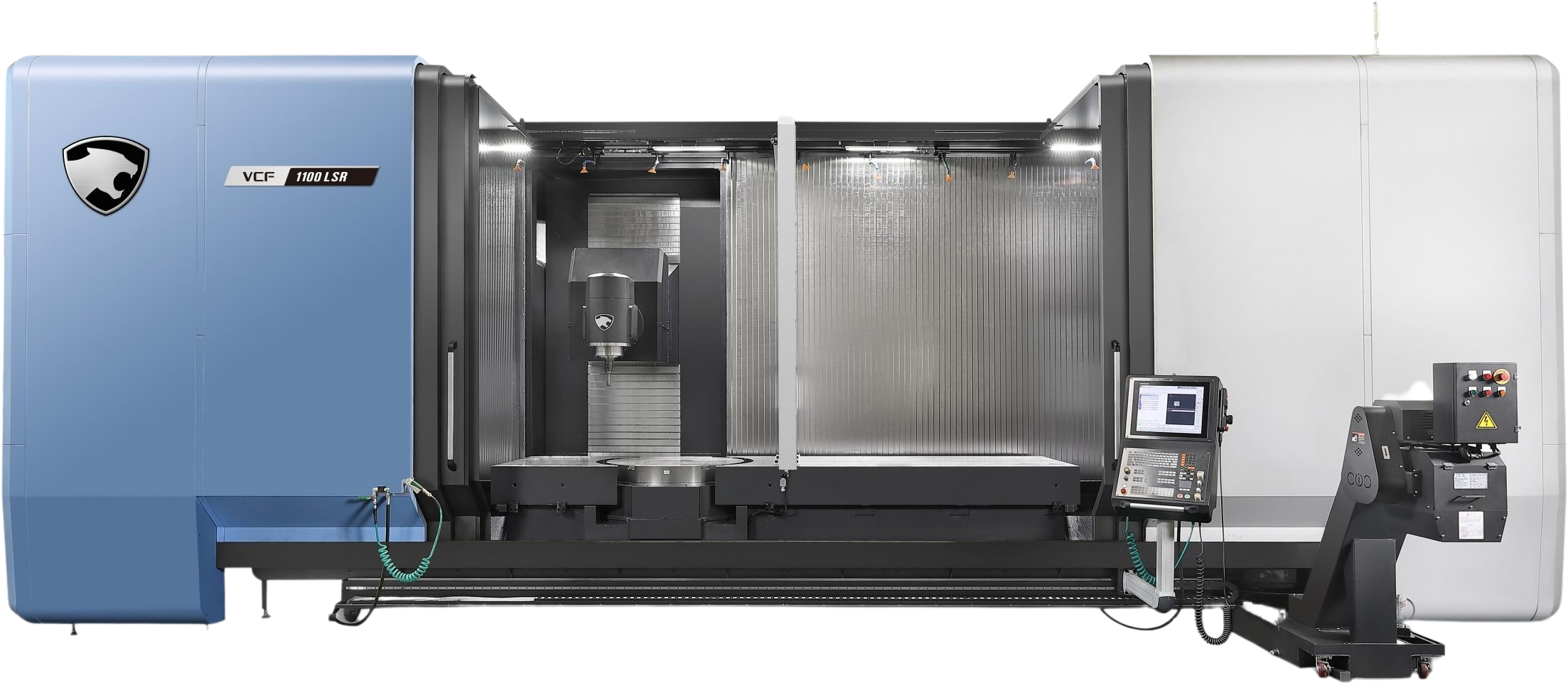

HM 1250W

Horizontal Machining Centres

- 45kW/3000rpm spindle

- 316ea tool stations

- 11526 x 5822 x 4581 mm (LxWxH)

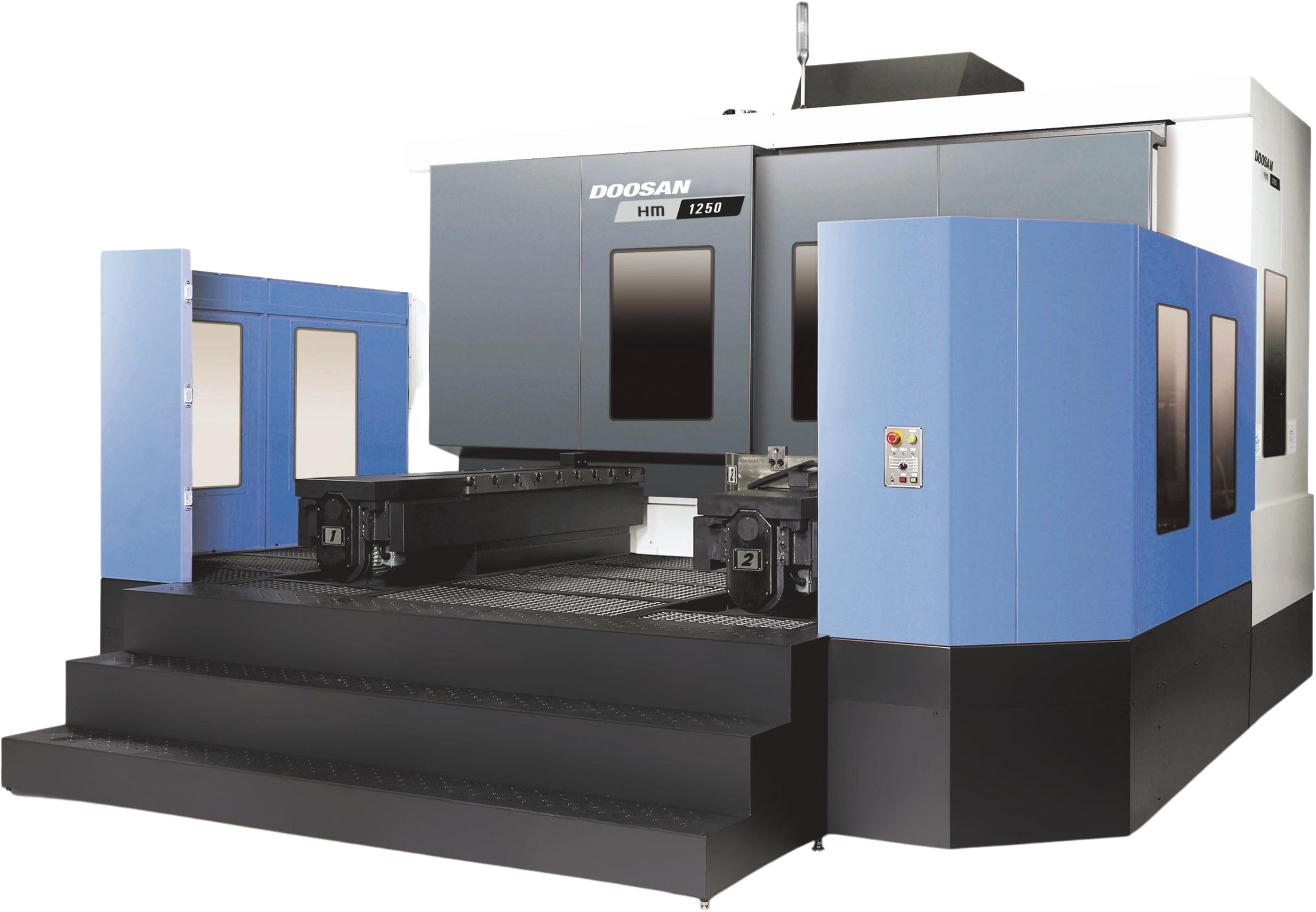

HM 1250

Horizontal Machining Centres

- 26kW/6000rpm spindle

- 316ea tool stations

- 10530 x 5822 x 4130 mm (LxWxH)

HM 1000

Horizontal Machining Centres

- 26kW/6000rpm spindle

- 316ea tool stations

- 9657 x 5822 x 3885 mm (LxWxH)

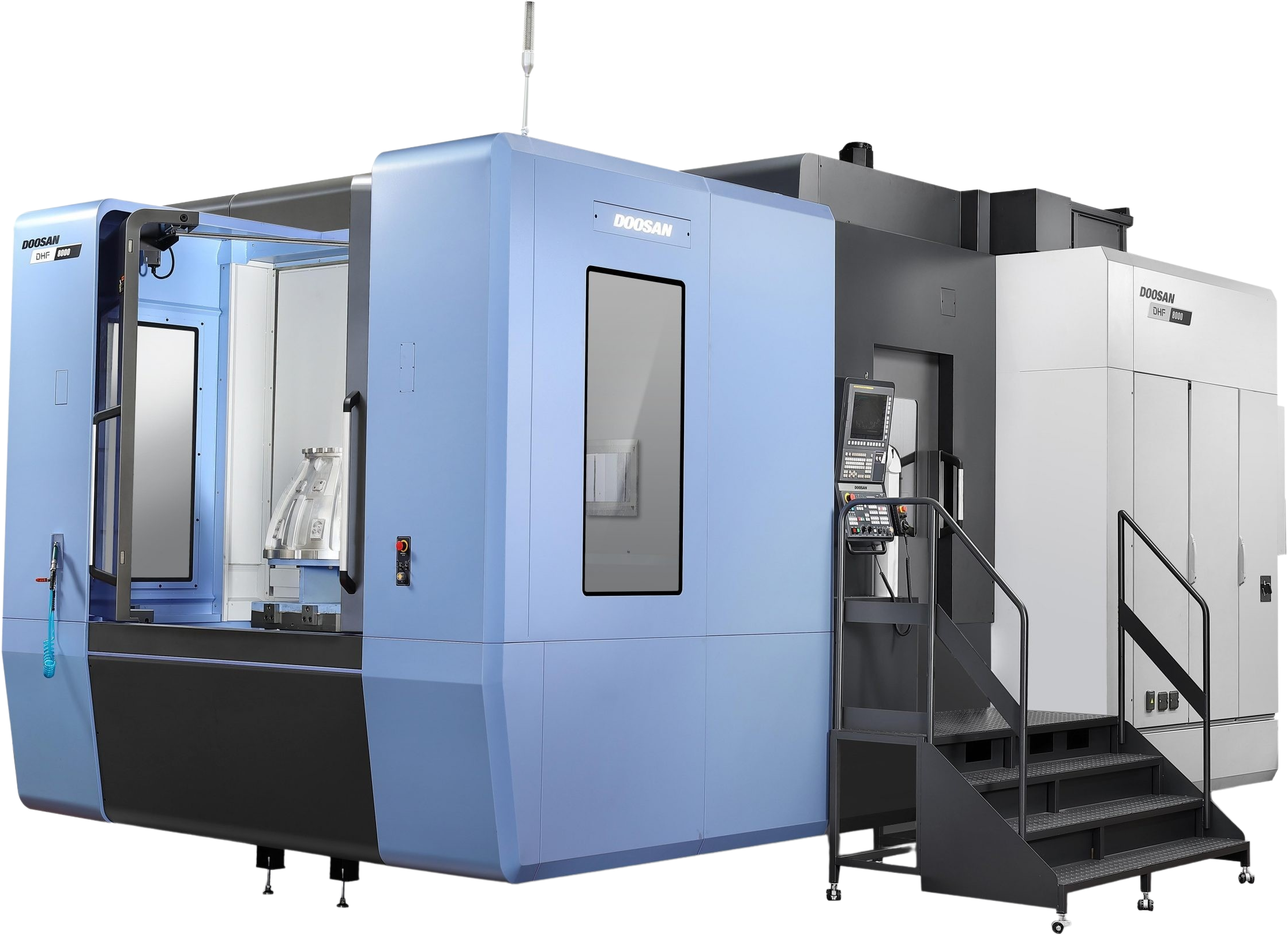

NHM 8000

Horizontal Machining Centres

- 35kW/6000rpm spindle

- 376ea tool stations

- 7380 x 4325 x 3760 mm (LxWxH)

NHM 6300

Horizontal Machining Centres

- 35kW/6000rpm spindle

- 376ea tool stations

- 6410 x 3930 x 3495 mm (LxWxH)

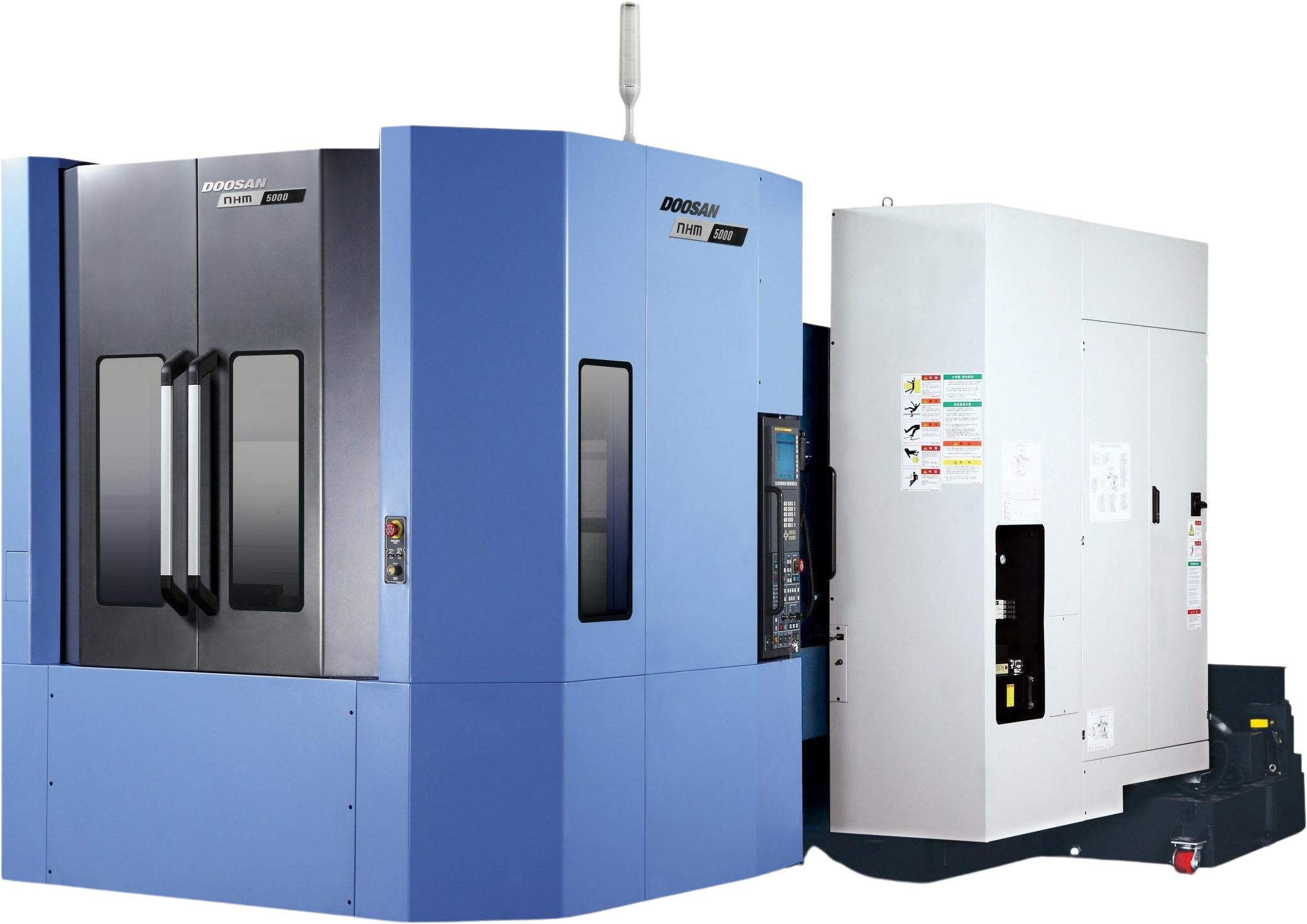

NHM 5000

Horizontal Machining Centres

- 25kW/6000rpm spindle

- 376ea tool stations

- 6055 x 3670 x 3330 mm (LxWxH)

Filter

Related Case Studies

Recognising excellence!

Award Winning Vertical 5-Axis CNC Machining Centre

DN Solutions scoop up two prestigious and coveted RED DOT Design Awards for their new, advanced DVF 5000 and DNX 2100 machine tool models.

High precision manufacturing with fast processing speeds

DNM 5700 Vertical Machining Centre

Leading manufacturing specialist, AEP Precision Engineering, invests in a new DN Solutions’ high-performance vertical machining centre to improve process efficiencies and productivity.

Putting higher productivity and increased process efficiencies in its sights!

SVM 4100 Vertical Machining Centre

PRS Engineering, a leading air rifle accessories manufacturing specialist, has recently increased its in-house machining capacity and capabilities by investing in two new advanced DN Solutions’ machine tools from Mills CNC.

Get in touch

If you’d like to find out more about any of our machines, if you’d like a brochure or want to book a demo, then we’d love to hear from you. Whether you’re looking for a specific CNC machining centre or want to know more about our turnkey or automated solutions, then Mills CNC can help.